Plastic Cable Conduit

When it comes to electrical installations, choosing the right cable conduit is crucial for both safety and functionality. While there are several excellent options available, the plastic conduit system stands out as the most versatile choice. At Meteor Electrical, we offer high-quality PVC conduit systems that are flexible and adaptable to a variety of settings. Whether you're working on a residential project or an industrial installation, our plastic cable conduits provide the protection and reliability you need.

For those new to the world of cable conduits, understanding the basics can make all the difference in your project's success. To help you navigate this essential component of electrical work, we’ve put together a comprehensive guide on plastic cable conduits. We’ll delve into what they are, their benefits, how to choose the best option, and tips for installation. Plus, we’ll link to authoritative resources from National Electrical Code (NEC), Electrical Safety Foundation International, and The PVC Pipe Institute to provide you with further insights and standards.

What Are Plastic Cable Conduits?

To truly grasp how plastic cable conduits work, it’s essential to start with the basics. PVC stands for polyvinyl chloride, a chemically resistant synthetic material widely used in various applications, including power lines and telecommunication cables. PVC cable conduits are designed to thread and protect wiring from electrical leakage and corrosion, ensuring that your electrical systems remain safe and efficient.

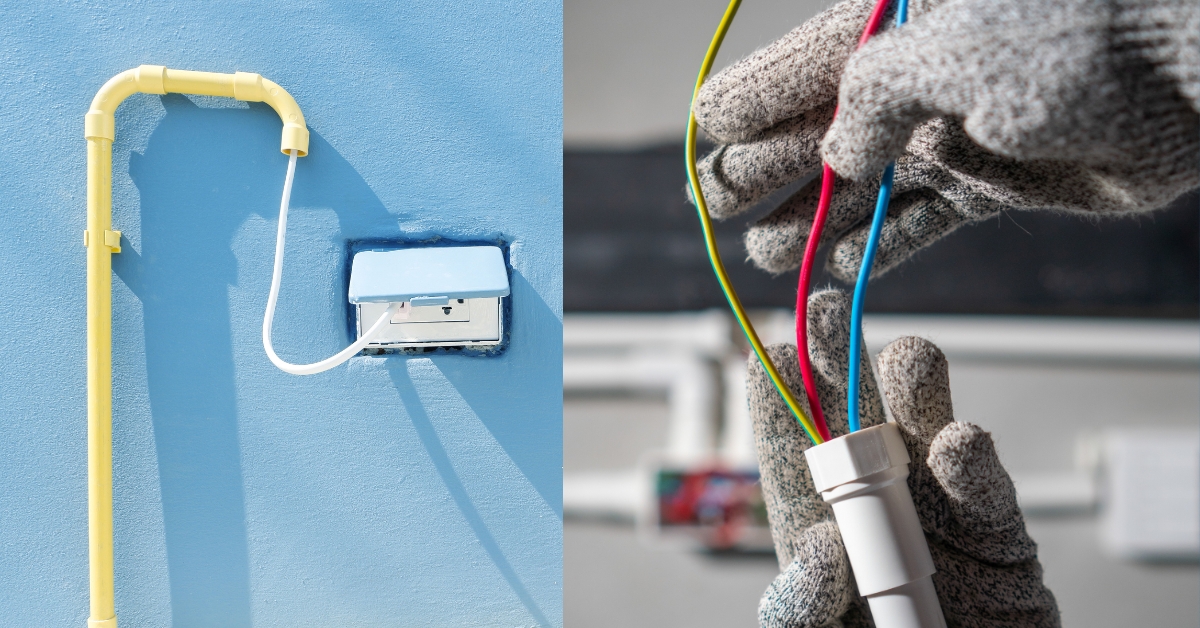

PVC conduits are renowned for their durability and toughness, capable of withstanding pressure and impacts that might otherwise damage your wiring. Additionally, they excel at repelling moisture and sunlight, making them an excellent choice for outdoor installations where environmental factors can pose significant threats to your electrical infrastructure. Available in a myriad of sizes, shapes, materials, and styles, PVC cable conduits can be tailored to fit a wide range of installation needs and demands.

Electricians often classify cable conduits based on wall thickness, material type, and mechanical stiffness. This classification system simplifies the selection process, ensuring that you choose the right conduit for your specific requirements. Before installation, it’s crucial to ensure that all cable conduits meet national electrical standards, which guarantees optimal performance and safety for your wiring system.

One of the standout advantages of using cable conduits is their ability to reduce the need for additional components like electrical boxes. For instance, metal conduits can serve the dual purpose of acting as a grounding wire, eliminating the need for separate grounding components. This not only simplifies the installation process but also enhances the overall efficiency of your electrical system.

What Is The Best Cable Conduit Plastic?

With a plethora of options available, selecting the right plastic conduit can be daunting. Fortunately, Meteor Electrical simplifies this process by offering a curated selection of high-quality plastic conduit systems designed to protect your wiring and enhance functionality. Let’s explore some of the top PVC conduits we offer:

Decoduct 32mm Flexible PVC Conduit

If flexibility is a priority for your project, the Decoduct 32mm PVC conduit is an excellent choice. Manufactured with a premium PVC coating, this conduit system is versatile enough to handle both outdoor and indoor installations seamlessly. It adheres to local and international electrical standards, ensuring safety and reliability across various applications.

With a 32mm diameter, this conduit provides ample space for larger wiring needs, accommodating multiple cables or thicker wires with ease. Its flexible design allows for easy bending and manipulation around corners and tight spaces, making it a practical solution for complex electrical layouts. Additionally, this conduit is rated for use in temperatures ranging from -5°C to 60°C, making it suitable for diverse environmental conditions.

The UV-stabilized PVC material offers enhanced protection against harmful sunlight exposure, preventing degradation over time and ensuring the longevity of your electrical system.

Cablecraft’s Betaflex 25mm PVC Conduit

For those seeking a conduit with superior hazard protection, Cablecraft’s Betaflex 25mm PVC conduit is an ideal option. Designed for durability, Betaflex conduits offer exceptional protection in both residential and industrial settings. These conduits are self-extinguishing and halogen-free, which means they do not release toxic gases when exposed to fire, enhancing overall safety.

Cablecraft has engineered Betaflex conduits to withstand various environmental challenges, making them suitable for almost any location. Whether you’re working on a new installation or upgrading an existing system, Betaflex conduits provide the reliability and safety you need.

At Meteor Electrical, we offer a wide array of PVC conduits, including these top-tier options. Visit our website today to explore our full range and find the perfect PVC conduit for your specific needs.

| Product Name | Diameter | Material | Flexibility | Temperature Range | UV Resistance | Key Features | Ideal Applications |

|---|---|---|---|---|---|---|---|

| Decoduct 32mm Flexible PVC Conduit | 32mm | High-Quality PVC | Highly Flexible | -5°C to 60°C | UV-Stabilized |

|

Outdoor and indoor installations requiring flexibility and durability |

| Cablecraft Betaflex 25mm PVC Conduit | 25mm | PVC (Self-Extinguishing, Halogen-Free) | Moderate Flexibility | -10°C to 70°C | UV-Stabilized |

|

High-risk environments, residential and industrial electrical systems |

| Meteor UltraShield 20mm PVC Conduit | 20mm | Reinforced PVC | Flexible | -10°C to 65°C | UV-Resistant |

|

Commercial buildings, areas with high mechanical stress |

| Meteor FlexiGuard 40mm PVC Conduit | 40mm | Flexible PVC | Extremely Flexible | -15°C to 75°C | UV-Stabilized |

|

Large-scale industrial installations, data centers |

| Meteor EcoConduit 16mm PVC Conduit | 16mm | Eco-Friendly PVC | Semi-Flexible | -5°C to 60°C | UV-Protected |

|

Residential wiring, small-scale commercial projects |

What Are Plastic Cable Conduits Used For?

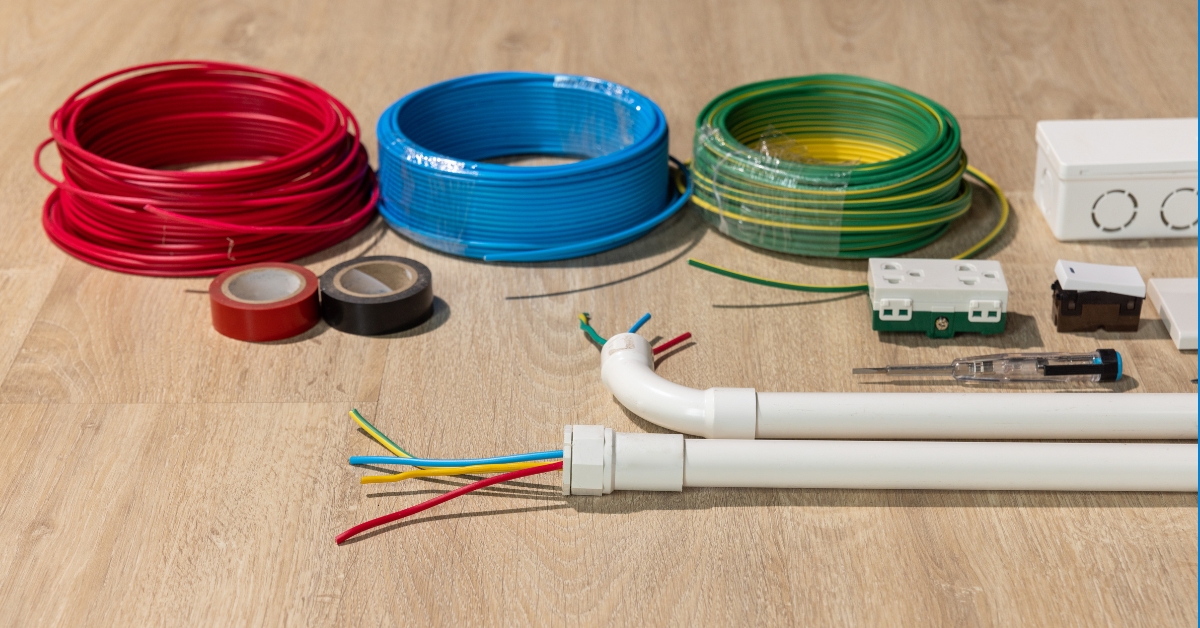

While storing wiring and cables is a primary function of cable conduits, their utility extends far beyond mere storage. Here are some key applications and benefits of using cable conduits:

Meet Codes and Regulations

Adhering to building safety standards and electrical codes is non-negotiable in any construction or renovation project. Conduits are often mandated by building codes to ensure the safe installation and protection of electrical systems. Whether you’re embarking on a new construction or updating an old system, using the appropriate conduit ensures compliance with safety regulations and prevents potential legal and safety issues down the line.

Protect Wiring From Damage

One of the primary reasons electricians favor cable conduits is the comprehensive protection they offer to wiring. Conduits safeguard cables against moisture, fire, chemicals, impact, and other hazards that can compromise the integrity of your electrical system. While individual wires come with their own insulation, conduits add an extra layer of protection, enhancing overall safety and durability.

Eliminate Interference

Electromagnetic interference (EMI) can significantly impact the performance of electrical systems, leading to disruptions and inefficiencies. Cable conduits help mitigate EMI by shielding cables, ensuring that your wiring operates smoothly and without interference. This is particularly important in environments with high electrical activity or sensitive equipment.

Keep Wiring Organized

A cluttered and disorganized wiring setup can be a nightmare to manage and maintain. Cable conduits provide a neat and orderly way to route and organize wires, making installations cleaner and easier to work with. Organized wiring not only looks better but also simplifies troubleshooting and maintenance tasks, reducing the risk of accidental damage to cables.

What Is The Difference Between A PVC Pipe And Conduit?

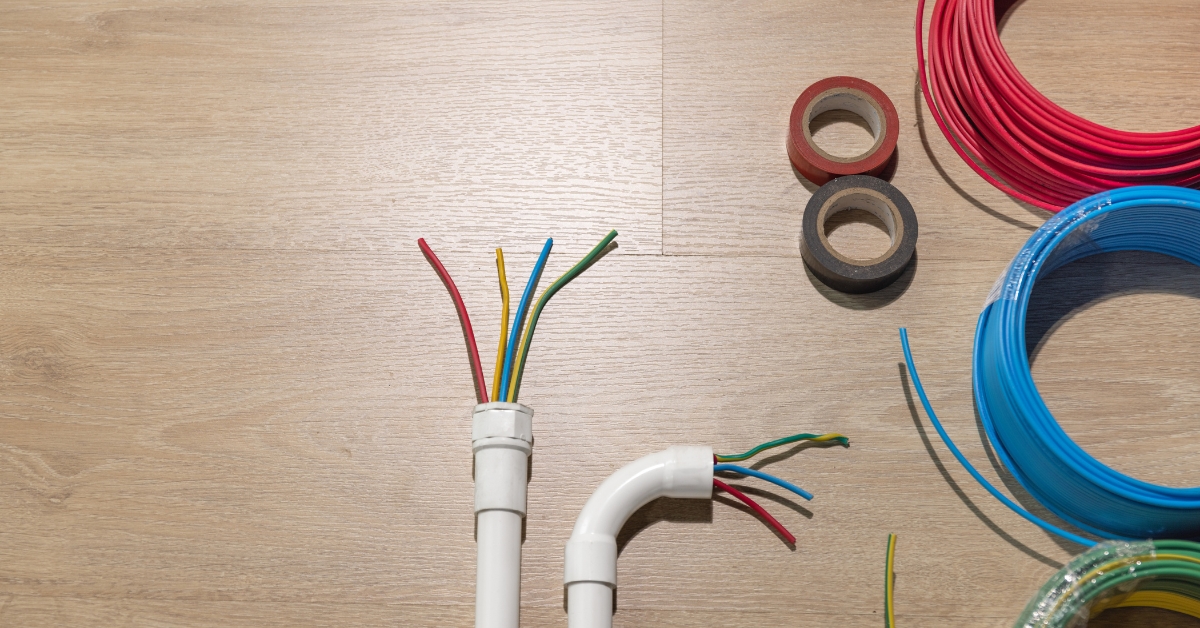

While PVC pipes and conduits are often confused due to their similar appearance and material composition, they serve distinct purposes and should not be used interchangeably. Understanding the key differences between the two is essential for selecting the right component for your specific application.

Pressure Capacity

One of the primary distinctions lies in their pressure ratings. PVC pipes are specifically designed for plumbing applications and are tested to withstand water pressure. The pressure rating is typically printed on the pipe itself, ensuring that it can handle the demands of fluid transportation without failure.

In contrast, PVC conduits do not require pressure ratings since they are intended for electrical wiring rather than fluid flow. Using PVC conduits for plumbing can lead to significant issues, including leaks and potential electrical hazards, as they are not engineered to handle pressure.

Colour

Colour is a quick and easy way to differentiate between PVC pipes and conduits. PVC pipes are generally white, a colour associated with plumbing and water transport. On the other hand, PVC cable conduits are typically black or grey, aligning with their role in electrical installations.

Wall Thickness

The wall thickness of PVC pipes is greater than that of conduits. This increased thickness ensures that PVC pipes can withstand the physical stress and pressure associated with plumbing applications. The robust walls prevent bending and ensure the pipe remains intact even under high-pressure conditions.

PVC conduits have thinner walls to allow for flexibility and ease of installation in electrical systems. Despite the reduced thickness, PVC conduits provide ample protection for wiring, balancing durability with the need for flexibility during installation.

UV Degradation

PVC conduits are often installed outdoors, where they are exposed to UV rays and sunlight. To combat potential degradation, many PVC conduits are UV-stabilized, allowing them to withstand prolonged sunlight exposure without cracking or becoming brittle.

Conversely, PVC pipes are typically installed indoors or underground, where they are shielded from direct sunlight. As a result, they are not UV-stabilized and can degrade if exposed to ultraviolet rays, making them unsuitable for outdoor use.

Connections And Placement

The methods for connecting PVC pipes and conduits also differ. PVC conduits feature flared openings that allow for easy attachment without the need for couplers. Specialized conduit clips can be used to secure them, but these clips are not compatible with PVC pipes.

On the other hand, PVC pipes often require couplers and cement to join sections together securely. These materials are specifically designed for plumbing applications and are incompatible with conduits, underscoring the importance of using each component for its intended purpose.

What Are Plastic Conduit Fittings, And How Do They Work?

To create a functional and reliable conduit system, plastic conduit fittings are essential. These fittings play a crucial role in connecting conduit sections, attaching conduit to electrical devices, and providing additional support to ensure the system remains secure and efficient.

Conduit Bodies

Conduit bodies are tubular fittings with openings at both ends, facilitating seamless bends and connections within the conduit system. Available in various sizes and designs, these fittings allow for easy placement and adjustment of conduits during installation. Clear labeling on conduit bodies helps identify the correct type and size needed for specific sections of the system.

Conduit Clips

For long runs of conduit, additional support is necessary to prevent sagging or breaking. Conduit clips and clamps are mounted on walls or ceilings using bolts or screws, securing the conduit in place. It’s important to adhere to regulatory and safety codes when selecting the appropriate size and type of conduit clip to ensure maximum support and compliance.

Conduit Couplings

Conduit couplings are used to join multiple conduits, creating a continuous and integrated network. While PVC tubing can sometimes be connected without couplings using belled ends, couplings are essential in sections where conduits have been cut or need to be joined. Available in various sizes and often featuring internal threading, conduit couplings ensure a secure and stable connection between conduit sections.

Credit: GSH Electrical

Finding The Best Conduit Fittings

Selecting the right conduit fittings is as important as choosing the conduits themselves. At Meteor Electrical, we offer a comprehensive range of conduit fittings to complement our plastic conduit systems. Whether you need conduit bodies, clips, or couplings, our selection ensures that you can create a cohesive and reliable conduit network.

For instance, Unicrimp’s range of conduit clips includes white cable clips designed for 22-26mm round fixtures. Made from high-grade polyethylene, these clips offer excellent flexibility in low-temperature environments, ensuring your wiring remains secure and organized. Properly installed conduit clips prevent damage to your wiring by keeping cables neatly in place, reducing the risk of wear and tear over time.

How Do You Run Cables And Wiring In Conduits?

Installing cables and wires within conduits can be challenging, especially when navigating bends and tight spaces. Here are some effective methods to streamline the process:

The String Method

The string method is ideal for short, straight conduit runs. This technique involves pushing a rod with a string attached through the conduit. Once the rod reaches the end, you can pull the string back, bringing the wire along with it. This simple method is effective for straightforward installations without complex bends.

A Conduit Piston

A conduit piston, sometimes referred to as a conduit mouse, is a specialized tool designed to pull wires through conduits. By attaching the wire to the piston and creating a vacuum, the piston propels the wire along the conduit. This method is particularly useful for conduits with multiple bends and twists, though it’s best suited for shorter runs where precise control is needed.

The Fish Tape Method

Fish tape is a standard tool in electrical work, consisting of a long, flat metal wire wound around a spool. To use this method, you feed the fish tape through the conduit and attach the electrical wire to the end. By pulling the tape back through, the wire is guided through the conduit. This method is versatile and works well for various conduit lengths and configurations.

What Type Of Wiring Is Run Through Cable Conduits?

Cable conduits are designed to accommodate a wide range of wiring types, but certain wires are particularly well-suited for conduit systems. The most common types include THWN and THHN wires:

THWN Wires

THWN stands for Thermoplastic Heat and Water-resistant Nylon-coated. These wires feature thermoplastic insulation that provides excellent resistance to heat and moisture, making them ideal for environments where exposure to water or high temperatures is a concern. The nylon coating adds an extra layer of protection, enhancing the wire’s durability and longevity within conduits.

THHN Wires

THHN stands for Thermoplastic High Heat-resistant Nylon-coated. Similar to THWN wires, THHN wires have thermoplastic insulation but offer even higher heat resistance. They often come with an additional nylon coating, providing superior protection against environmental factors. THHN wires are commonly used in both residential and commercial electrical systems, making them a versatile choice for conduit installations.

Modern electrical installations typically require a grounding wire to ensure safety and compliance with electrical codes. While non-metallic cables require a separate grounding wire, metal conduits can sometimes serve this purpose, eliminating the need for additional components. However, it’s essential to verify current electrical standards, as older fittings may have different requirements.

Credit: eFIXX

Additional Tips for Choosing and Installing Plastic Cable Conduits

To ensure the longevity and effectiveness of your electrical system, consider the following tips when selecting and installing plastic cable conduits:

1. Assess Your Needs: Before choosing a conduit, evaluate the specific requirements of your project, including the number of cables, environmental conditions, and any applicable regulations.

2. Quality Matters: Invest in high-quality conduits and fittings to ensure durability and reliability. Cheap or subpar materials can lead to failures and safety hazards down the line.

3. Plan Your Layout: Carefully plan the routing of your conduits to minimize bends and ensure easy access for maintenance. A well-planned layout reduces installation time and potential issues during operation.

4. Follow Standards: Adhere to national and local electrical codes to ensure compliance and safety. Consulting resources like the National Electrical Code can provide valuable guidelines.

5. Use Proper Tools: Equip yourself with the right tools for installation, such as conduit cutters, fish tapes, and appropriate fittings, to make the process smoother and more efficient.

6. Seek Professional Help: If you’re unsure about any aspect of conduit installation, consider consulting a licensed electrician to ensure the job is done correctly and safely.

Why Choose Meteor Electrical for Your Plastic Cable Conduits?

At Meteor Electrical, we pride ourselves on offering a comprehensive selection of high-quality plastic cable conduits and fittings to meet the diverse needs of our customers. Our products are sourced from reputable manufacturers known for their durability, safety, and compliance with industry standards.

Why Meteor Electrical?

- Extensive Selection: From flexible PVC conduits to durable Betaflex options, our range caters to a wide array of electrical applications.

- Quality Assurance: We ensure that all our products meet stringent quality standards, providing you with reliable and safe solutions.

- Expert Support: Our knowledgeable team is always ready to assist you in selecting the right products for your specific needs.

- Competitive Pricing: We offer excellent value for money, ensuring you get top-quality products without breaking the bank.

- Convenient Shopping: Browse and purchase our products easily through our online store, with fast shipping and excellent customer service.

Whether you’re undertaking a DIY project or managing a large-scale electrical installation, Meteor Electrical is your trusted partner for all your plastic cable conduit needs. Explore our extensive product range today and experience the Meteor Electrical difference.

Conclusion

Selecting the right plastic cable conduit is essential for ensuring the safety, efficiency, and longevity of your electrical installations. At Meteor Electrical, we offer a wide range of high-quality PVC conduit systems designed to meet diverse needs and comply with stringent safety standards. From flexible options like Decoduct 32mm to durable solutions like Cablecraft’s Betaflex 25mm, our products provide the protection and reliability you require.

Understanding the differences between PVC pipes and conduits, choosing the right fittings, and employing effective installation methods are all critical components of a successful electrical setup. By following best practices and utilizing top-quality materials, you can create an organized, safe, and efficient electrical system that stands the test of time.

For more information, expert advice, and to browse our full range of products, visit Meteor Electrical today. Let us help you master your electrical projects with our superior plastic cable conduit solutions.

Frequently Asked Questions (FAQs)

1. What are the main advantages of using plastic cable conduits over metal conduits?

Plastic cable conduits, such as PVC, offer several benefits including lightweight installation, corrosion resistance, flexibility, and cost-effectiveness. Unlike metal conduits, they are non-conductive, reducing the risk of electrical interference and eliminating the need for additional grounding in some cases.

2. How do I determine the right size of PVC conduit for my electrical project?

Choosing the correct conduit size depends on the number and thickness of the cables you plan to run. A general guideline is to use the National Electrical Code (NEC) conduit fill tables, which provide maximum fill capacities based on conduit diameter and cable type. Consulting with a professional electrician or referencing resources like the National Electrical Code can help ensure accurate sizing.

3. Are plastic cable conduits suitable for outdoor installations?

Yes, plastic cable conduits are ideal for outdoor use. Many PVC conduits are UV-stabilized to resist sunlight and prevent degradation over time. Additionally, their moisture-resistant properties make them suitable for various environmental conditions, ensuring the protection and longevity of your electrical wiring.

4. Can PVC conduits be used for plumbing purposes instead of electrical applications?

No, PVC conduits and PVC pipes are designed for different applications and should not be used interchangeably. PVC conduits are specifically made for electrical wiring and lack the necessary pressure ratings required for plumbing. Using conduits for plumbing can lead to leaks and electrical hazards.

5. What are the best practices for installing conduit fittings to ensure a safe and efficient electrical system?

*To ensure a secure and effective installation, always use the appropriate conduit fittings for your specific conduit type and application. Follow these best practices:

- Proper Alignment: Ensure conduits are properly aligned and securely connected using the correct fittings.

- Support and Securing: Use conduit clips and clamps to support conduits at regular intervals, preventing sagging and movement.

- Sealing Connections: For outdoor or moisture-prone areas, use weather-resistant fittings and sealants to protect connections.

- Compliance with Codes: Adhere to local electrical codes and standards, such as those outlined by the National Electrical Code, to ensure safety and compliance.