The Ultimate Guide to Cable Conduits: Safeguarding Your Wires Behind Walls

Imagine your home or office without the unsightly mess of exposed wires. Picture a clean, organized space where cables are protected from wear and tear, ensuring your electrical systems run smoothly for years. This isn't a dream—it's the power of cable conduits. Here at Meteor Electrical, we understand the importance of seamless, safe, and efficient wiring.

In this comprehensive guide, we'll explore everything you need to know about cable conduits, from their types and benefits to the best installation practices. Whether you're wondering about cables in walls regulations UK, the need for in wall conduit, or why you might ask, "do electrical wires need to be in conduit UK?"—we’ve got you covered. Let’s dive into how to protect and organize your wiring with the right conduit system.

What Are Cable Conduits and How Do They Work?

Cable or electrical conduits are robust plastic or metal tubes that house essential electrical wires and cables. Often referred to as trunking, these systems are designed to shield wires from various hazards, whether installed indoors or outdoors, in finished or unfinished spaces. According to The Fire Protection Association (TFPA), proper conduit use is critical to ensuring fire safety standards are met.

Cable conduits are available in various sizes, shapes, materials, and styles to suit different installation needs. While metallic conduits are the most common, you can also find options made from plastic, fibre, and fired clay. These conduits provide excellent protection due to their thick outer layers, and electricians often categorize them by wall thickness, material, and mechanical stiffness.

It's crucial to ensure that all cable conduits meet national electrical standards before installation to guarantee they offer optimal protection for your wiring system. Organizations like BEAMA stress the importance of adhering to standards for safety and efficiency. Most materials chosen for conduits are valued for their corrosion resistance, mechanical protection, and cost-effectiveness, including labor and material expenses.

One significant advantage of metal conduits is that they can function as grounding wires, eliminating the need for additional components (ESFI).

Concealed Conduit Wiring: The Best Installation Method

When it comes to installations, many homeowners ask, "do you need conduit in walls?" or "do I need to use conduit in walls?" Especially in the UK, regulations about burying cables in walls rules. Concealed wiring involves installing electrical conduits inside walls, floors, or ceilings, hiding all wiring from view. This method is typically covered with plaster or similar material, seamlessly blending with the surrounding surface. Concealed wiring not only preserves the aesthetics of your space but also offers numerous other benefits:

- Ensures Wire Safety: Concealed wiring protects wires from environmental hazards, reducing the risk of electrocution, electrical fires, and other dangers, as noted by HSE.

- Protection from Hazards: Properly installed concealed wiring shields cables from moisture, heat, dust, sunlight, and other elements, extending their lifespan and reducing maintenance needs (The Fire Protection Association).

- Improves Aesthetics: By hiding unsightly cables and wiring, you can achieve a clean, minimalist look in your home (Architectural Digest).

- Easy to Install: Concealed wiring requires a one-time installation process, making it a cost-effective solution for residential and commercial properties (HomeAdvisor).

When deciding on in wall conduit for your project, consider these significant advantages. Concealed wiring methods become especially important when planning areas where aesthetic appeal and safety are paramount.

Credit: The Home Depot

Uses of Cable Conduits

Cable conduits do more than just house wires and cables; they play several crucial roles in maintaining a safe and efficient electrical system:

- Compliance with Codes and Regulations: Cable conduits are essential in meeting building safety standards and electrical codes. They ensure that electrical installations are safe, standardized, and up to code, vital for residential and commercial buildings. For instance, Building Codes Assistance Project provides detailed insights into compliance requirements.

- Design Versatility: With conduits, you can achieve flexible cable configurations and installations. Whether you're navigating tight spaces or accommodating complex wiring setups, conduits provide the adaptability needed to route cables efficiently and safely (International Association of Electrical Inspectors).

- Damage Protection: One of the primary functions of cable conduits is to shield wires from potential damage. They offer an extra layer of protection against environmental factors like moisture, fire, chemicals, and physical impacts, thereby prolonging the life of your cables and enhancing overall safety (UL Solutions).

- Electromagnetic Interference Reduction: Cable conduits can significantly reduce electromagnetic interference, ensuring that your cables function optimally without disruptions. This is particularly important in environments with a lot of electronic equipment, where interference can affect performance (IEEE Standards Association).

- Organized Wiring: Keeping your wiring organized is crucial for maintenance and safety. Conduits help manage and protect cables, making it easier to identify, repair, and upgrade wiring systems as needed. This organization not only improves functionality but also maintains a clean and orderly appearance (Better Homes & Gardens).

Choosing the Right Cable Conduit

Selecting the right conduit for your project requires careful consideration of several key factors:

- Installation Requirements: Think about where and how the conduit will be installed. Different environments and applications may require specific types of conduits, such as flexible options for tight spaces or rigid ones for straight runs. For instance, This Old House provides advice on selecting the right conduit for various spaces.

- Cost: Evaluate the costs involved, including materials and labor. Some conduits may be more expensive upfront but offer long-term savings through durability and reduced maintenance (Home Depot).

- Potential Hazards: Assess the environmental and physical hazards that the conduit needs to withstand. This includes exposure to moisture, chemicals, high temperatures, and physical impacts (Energy.gov).

- Variety: Choose a conduit that meets your specific needs across various settings. Different projects may require different types of conduits, such as non-metallic options for wet areas or metal conduits for high-impact environments (Lowe's).

- Assembly Time: Consider the ease of installation. Some conduits are designed for quick and straightforward assembly, which can save time and reduce labor costs. It's important to balance ease of installation with the durability and protection the conduit provides (Angi).

By asking "do electrical wires need to be in conduit UK?" you can determine whether your system requires extra safety measures. Regulations and safety guidelines often dictate that wiring, especially in walls, should be run through a conduit to protect it from potential hazards, ensuring compliance with local codes.

Types of Cable Conduits

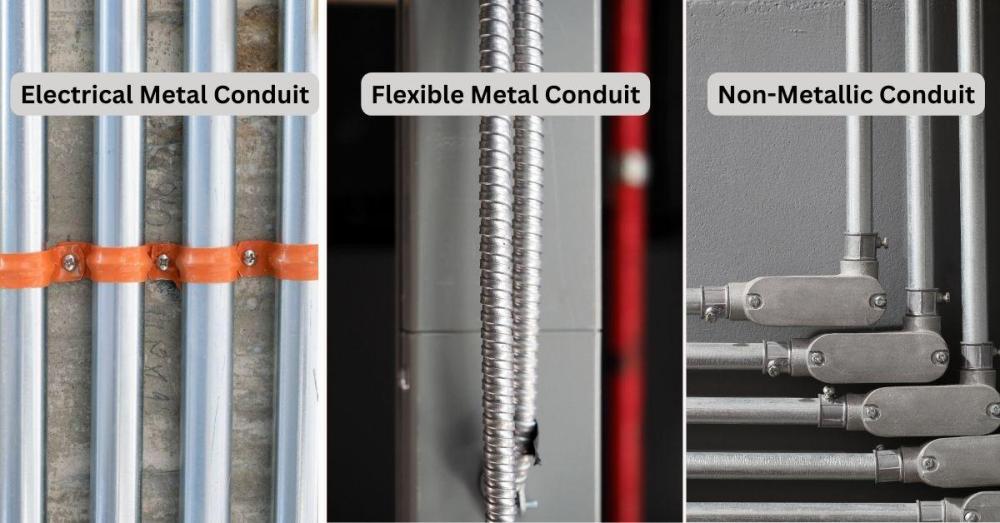

Cable conduits come in various styles and materials, each designed for specific needs and applications:

Electrical Metal Conduit (EMT)

Known for its rigidity, EMT is a popular choice for both exposed and concealed installations. Made from galvanized steel, it offers robust protection and is often used in commercial and industrial settings. Its thin walls make it relatively easy to bend and install, making it versatile for a wide range of applications. Ask yourself: "Does electrical cable need to be in conduit?" For durability and grounding, EMT is often the answer.

Electrical Non-Metallic Conduit (ENT)

This flexible plastic tubing is perfect for residential walls and concrete structures. ENT is lightweight, easy to install, and provides excellent protection against moisture and corrosion, making it ideal for environments where metal conduits may not be suitable. When considering cable conduit in wall solutions, ENT often meets the mark due to its flexibility and resistance to environmental factors.

Flexible Metal Conduit (FMT)

With its spiral shape, FMT is highly adaptable and easy to bend, allowing it to navigate around obstacles. This type of conduit is often used in short-run, exposed areas, such as connecting lighting fixtures or other equipment where flexibility is crucial. For those asking, "When to use conduit for electrical wiring?" FMT provides an excellent solution for runs that require bending around obstructions.

Non-Metallic Liquid-Tight Flexible Conduit (NLFC)

Designed to be watertight and flame-resistant, NLFC is suitable for both indoor and outdoor installations. It is particularly useful in environments exposed to moisture, such as bathrooms, kitchens, and outdoor areas, where it provides superior protection against water ingress and other elements. This makes NLFC ideal when installing in wall conduit for power cable in moisture-prone areas.

Intermediate Metal Conduit (IMC)

Lighter and thinner than rigid metal conduits, IMC offers the same level of protection with added ease of installation. Its corrosion-resistant coating makes it ideal for outdoor and industrial applications where durability is essential, but weight and ease of handling are also considerations. For an interior electrical conduit that provides substantial strength without excessive bulk, IMC is a strong contender.

| Conduit Type | Material & Structure | Key Features | Advantages | Considerations |

|---|---|---|---|---|

| Electrical Metal Conduit (EMT) | Galvanized steel, rigid tubing | Rigid and durable, thin walls, grounding capabilities | Excellent protection, versatile for exposed and concealed installations | Requires specialized tools for bending; not ideal for very tight spaces |

| Electrical Non-Metallic Conduit (ENT) | Flexible plastic tubing | Lightweight, moisture and corrosion resistant | Easy to install, ideal for residential walls and concrete structures | Less robust than metal conduits in high-impact areas |

| Flexible Metal Conduit (FMT) | Spiral wound steel or aluminum | Highly flexible, easy to bend around obstacles | Adaptable for short-run, exposed areas; useful for lighting and equipment | May not provide as rigid protection as EMT |

| Non-Metallic Liquid-Tight Flexible Conduit (NLFC) | Flame-resistant, watertight flexible material | Water- and flame-resistant, maintains integrity in wet environments | Superior protection in moisture-prone areas, both indoor and outdoor | Typically more expensive; proper fittings needed for watertight seals |

| Intermediate Metal Conduit (IMC) | Lighter-weight metal with corrosion-resistant coating | Lighter than EMT with similar protection | Easier to handle than EMT, durable in outdoor and industrial settings | Slightly less common; may require specific fittings |

Ensuring Compliance: Regulations & Safety in the UK

In the UK, the wiring regulations are strict when it comes to burying cables in walls rules and the necessity for conduit usage. The Institution of Engineering and Technology (IET) outlines that where cables are concealed within walls, especially in commercial and new builds, the use of proper conduit is recommended for safety and compliance. Common questions include, "do electrical wires need to be in conduit UK?" or "cable wall conduit requirements." Adhering to these guidelines protects against hazards and ensures installations meet legal standards.

Common Questions:

Do I need to use conduit in walls?

Yes, using conduit in walls is often recommended by UK regulations to protect wiring from damage, ensure safety, and meet compliance standards. This practice prevents accidental exposure to electrical hazards and extends the lifespan of cables.

Does electrical cable need to be in conduit?

In many cases, the answer is yes—especially for cables inside walls or other concealed areas. This additional layer of protection helps in preventing fire risks and reducing wear and tear over time.

When to use conduit for electrical wiring?

Use conduit for electrical wiring in scenarios where the wiring is concealed, exposed to potential damage, or when running wires through walls and ceilings. If you're unsure whether a specific situation requires conduit, consult local building codes or a professional electrician.

Credit: eFIXX

Installing Conduit in Walls: Tips and Best Practices

Installing conduit in walls, floors, or ceilings can seem daunting, but following the best practices ensures safety and efficiency:

1. Plan Your Route:

Consider the path cables will take and avoid obstacles like studs, pipes, or HVAC ducts. If you need an in wall conduit for power cable, mapping the shortest, safest route first can save time and resources.

2. Measure Accurately:

Before cutting into walls, measure lengths for both cables and conduits to minimize waste and ensure a snug fit within walls. Compliance with regulations—such as cable conduit in wall guidelines—is critical here.

3. Drill Carefully:

When creating holes for conduits to pass through walls, floors, or ceilings, use the correct drill bits and safety gear. Avoid damaging existing structures or electrical systems.

4. Secure the Conduit:

Use proper clamps, brackets, and supports to fix the conduit in place. This prevents sagging or movement, which can damage cables over time.

5. Pulling Cables:

Once conduits are in place, carefully pull cables through them. If you encounter resistance, do not force the cables; instead, review the path for obstructions or consider using cable lubricant.

6. Sealing and Finishing:

After installation, seal any entry and exit points to protect against moisture and pests. Finally, patch up wall openings, ensuring everything is neat and flush with the surrounding surface.

Installing conduit in walls not only protects your cables but also answers questions like, "cable conduit for wall" and "wire conduit for wall" in practical terms. This approach keeps wiring concealed, organized, and compliant with safety standards.

Find Your Ideal Cable Conduit at Meteor Electrical

Choosing the right cable conduit is essential for the safety and efficiency of your electrical systems. Understanding the types and applications helps you make the best decision for your project’s needs. Whether you need rigid protection, flexibility, moisture resistance, or lightweight options, there is a conduit to meet your requirements.

At Meteor Electrical, we offer a wide range of high-quality conduits, including steel, PVC, and flexible options. Our products ensure your wiring is well-protected and your installations are safe and reliable. If you’re wondering, “do electrical wires need to be in conduit UK?” our experts can guide you to the perfect product for your application—whether it’s for interior electrical conduit or an in wall conduit solution.

Visit our store today to explore our selection of electrical conduits and find the perfect solution for your next project. Ensure the safety and efficiency of your electrical systems with Meteor Electrical—your trusted partner in electrical solutions.

Visit Meteor Electrical and explore our high-quality conduit systems to find the perfect solution for your needs.

FAQ: Cable Conduits

1. What is the purpose of using cable conduits?

Cable conduits protect electrical wiring from physical damage, moisture, and other environmental hazards. They also help organise and manage cables, making maintenance and future upgrades easier.

2. What are the different types of cable conduits?

There are several types of cable conduits, including Electrical Metal Conduit (EMT), Electrical Non-Metallic Conduit (ENT), Flexible Metal Conduit (FMT), Non-Metallic Liquid-Tight Flexible Conduit (NLFC), and Intermediate Metal Conduit (IMC).

3. Where can I use electrical metal conduits (EMT)?

EMT conduits are suitable for both exposed and concealed installations in commercial and industrial settings. They provide robust protection and are relatively easy to bend and install.

4. Why should I use flexible metal conduits (FMT)?

Flexible metal conduits are ideal for applications requiring easy bending and maneuverability. They are often used in short-run, exposed areas such as connecting lighting fixtures or other equipment.

5. What are the benefits of non-metallic liquid-tight flexible conduits (NLFC)?

NLFC conduits are watertight and flame-resistant, making them suitable for both indoor and outdoor installations where protection from moisture and other elements is crucial.

6. How do I choose the right conduit for my project?

Consider factors such as the installation environment, potential hazards, cost, and the specific requirements of your project. Different conduits offer various benefits, such as flexibility, moisture resistance, and ease of installation.

7. Can I use electrical non-metallic conduits (ENT) in outdoor applications?

ENT conduits are typically used in residential walls and concrete structures and are not recommended for outdoor applications due to their lower resistance to environmental factors compared to other types of conduits.

8. Where can I buy high-quality electrical conduits?

You can purchase a wide range of high-quality electrical conduits, including steel, PVC, and flexible options, from Meteor Electrical. Visit our store to explore our selection and find the perfect solution for your project.

9. Do cable conduits meet building safety standards?

Yes, cable conduits are designed to meet building safety standards and electrical codes, ensuring that your installations are safe, standardised, and compliant with regulations.

10. What is the difference between EMT and IMC conduits?

EMT conduits are thinner and easier to bend, suitable for lighter-duty applications, while IMC conduits are thicker, offering greater durability and corrosion resistance for more demanding environments.