External Cable Conduit

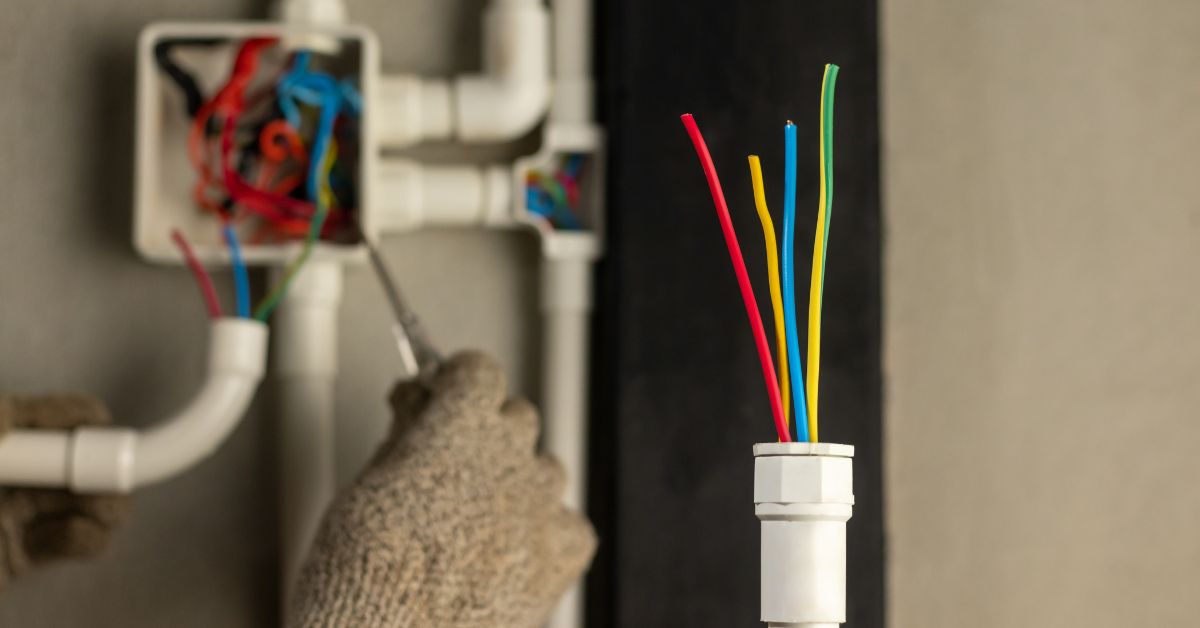

Have you ever wondered how to keep your external cables safe from unpredictable elements and everyday hazards? Whether it's harsh weather, physical damage, or general wear and tear, external cables are constantly under threat. Without proper protection, not only can the cables' coatings deteriorate, but their functionality can also be compromised, leading to costly repairs and potential safety risks.

While many external cables come with a basic protective layer, taking it a step further by installing an external cable conduit can significantly enhance their durability and performance. Cable conduits act as an extra shield, ensuring your wiring remains intact and operational for years to come.

At Meteor Electrical, we understand the importance of reliable cable management. In this comprehensive guide, we’ll walk you through everything you need to know about external cable conduits—from choosing the right type to installation tips—so you can make informed decisions and safeguard your electrical infrastructure effectively.

What Conduit Works Best for External Cables?

Not all conduit systems are built the same, as each has its own benefits and disadvantages. While many conduits work well indoors, they might not be suitable for outdoor external cables. Here’s a look at some of the best external cable conduits available:

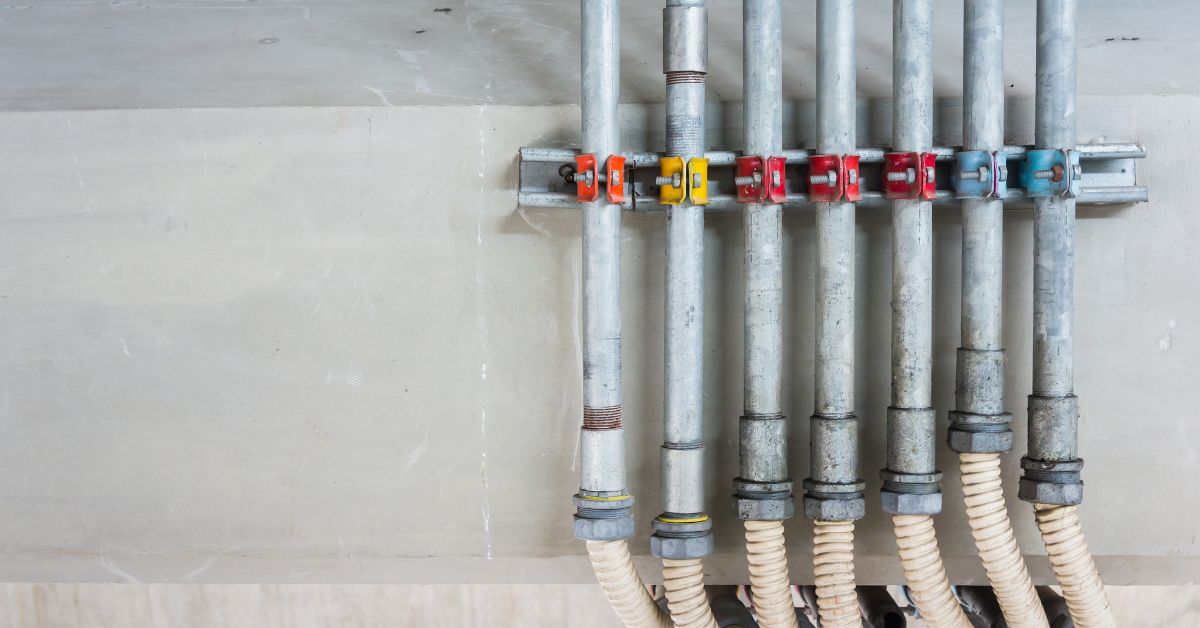

Electrical Metallic Conduits (EMT)

An electrical metallic conduit (EMT) is your best option if you want a flexible conduit system. Even though EMTs are ideal for indoor residential and light commercial installations, they work well outdoors too.

If you’re using this conduit with external cables, you need to assemble them with watertight fittings. This component has a thin-walled structure made of galvanised steel, commonly used as a non-flexible option.

Even though this conduit falls under the rigid category, you can bend its shape with a conduit bender tool to fit any installation. The lightweight material is malleable enough to contort into any desired shape.

Due to its manufacturing, electrical steel conduits can be applied in many locations. However, if an area experiences frequent physical damage, you should avoid using this material as it can be easily compromised, potentially ruining your wiring system.

You can use EMT conduits for both exposed or concealed wall installations. They are also suitable for floors and ceilings. The metal material allows them to be embedded into concrete or buried in the ground.

Electrical metallic conduits are connected with clamp-style fittings that slide onto the tubing. This configuration is secured with a set screw and locked into your desired area.

While EMTs provide decent protection for internal cables, they should not be used in hazardous locations (such as power plants) where they might experience severe damage.

Additionally, EMT conduits are unsuitable for wet areas or places with corrosive fumes and vapours. If you want to use EMTs in such locations, you must opt for corrosive-resistant tubing and gasket clamps.

Some electricians avoid using electrical metallic conduits in critical areas because the set screws in the clamps tend to loosen over time. To prevent this loosening, using a torque wrench will provide the correct tension to the screws, helping them last longer.

Credit: Electrician U

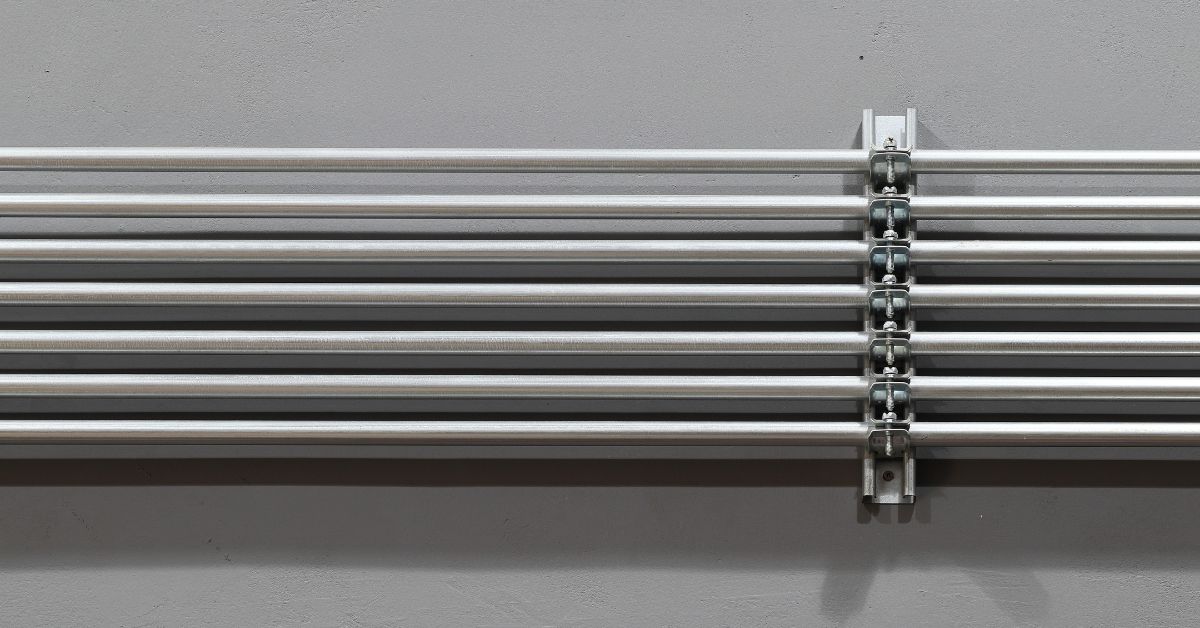

Rigid Metal Conduit (RMC)

As the name suggests, rigid metal conduits (RMC) offer the most protection as they are made from a tough and thick exterior. These are typically used for structural piping in homes to connect to utility service lines. RMCs are often joined with threaded connections to keep them together.

Coated with either aluminium or stainless steel, these conduits offer excellent protection against punctures, cuts, and other impacts. Apart from these two, you can also choose from other coatings depending on your needs.

When making this choice, remember where you’ll install the RMC. If you’re using it for outdoor applications, select

the coating accordingly.

One thing to note about RMCs is that they are more expensive and difficult to bend compared to other conduits. Despite these drawbacks, they are a great option for an external cable conduit system due to their superior protection.

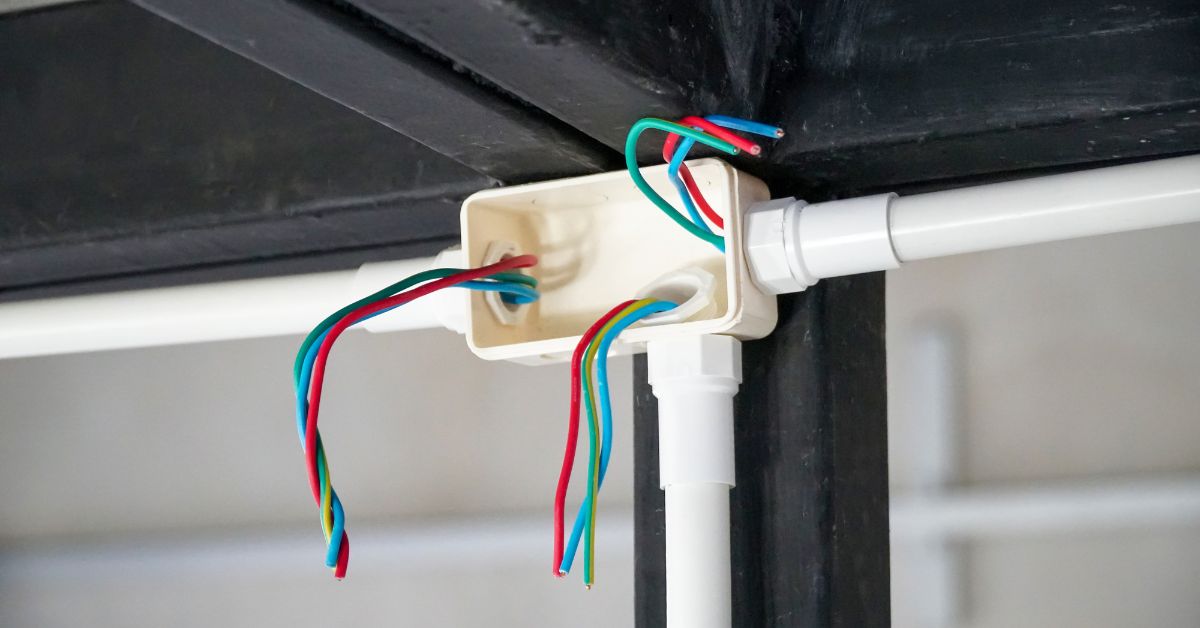

Non-Metallic Liquid-Tight Flexible Conduit (NLFC)

NLFC conduits are typically used in place of liquid-tight metal conduits. This conduit features a flexible PVC coating embedded into rigid PVC enforcements. Even though this conduit can bend, it still offers a watertight build and structure.

Non-metallic LF conduits provide moderate protection in dry, wet, or oily settings, making them ideal for external installation. Additionally, they possess flame-resistant properties.

These conduits are highly durable and suitable for both indoor and outdoor installations in commercial and industrial settings. They can also be placed in moisture-heavy areas such as pools and HVAC systems.

For enhanced protection, you can opt for liquid-tight flexible conduits made from polyamide instead of PVC. These provide resistance against acids, oils, benzene, flames, and other solvents. Polyamide conduits can also self-extinguish, making them suitable for demanding installations.

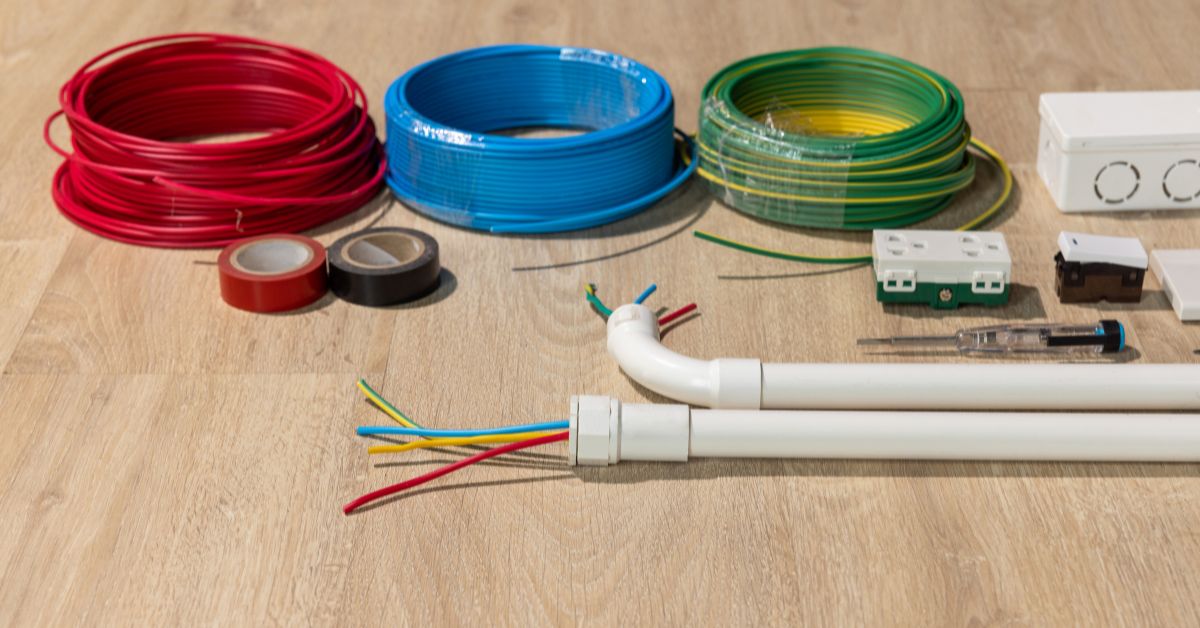

PVC Conduits

PVC conduits are a great choice if you’re looking for a lightweight, flexible option. PVC conduits are a non-metallic conduit system that works well in outdoor installations. This system is corrosion-resistant and easy to use.

PVC conduits can be installed above ground or underground, and their flexibility makes it easy to manoeuvre them through angled or curved pathways. However, this conduit is not suitable for areas with heavy impacts or high temperatures.

| Conduit Type | Material | Pros | Cons | Best Use Cases |

|---|---|---|---|---|

| Electrical Metallic Conduit (EMT) | Galvanised Steel |

|

|

|

| Rigid Metal Conduit (RMC) | Aluminium or Stainless Steel |

|

|

|

| Non-Metallic Liquid-Tight Flexible Conduit (NLFC) | PVC or Polyamide |

|

|

|

| PVC Conduit | Polyvinyl Chloride (PVC) |

|

|

|

| Conduit Bodies | Various (Metal, PVC) |

|

|

|

| Conduit Clips | Polyethylene or Metal |

|

|

|

How Do External Cable Conduits Work?

Cable conduits, also known as electrical conduits or trunking, are plastic or metal tube structures that hold essential electrical wires and cabling. These systems can be either rigid or flexible, depending on the installation requirements.

The primary purpose of a conduit is to protect wires from various hazards, ensuring longevity and safety. They can be used in both unfinished or exposed indoor and outdoor settings.

To accommodate a wide variety of installations and demands, cable conduits come in various sizes, shapes, materials, and styles. The most common material for conduits is metal, but you can also find options made from plastic, fiber, and fired clay. These structures are designed to provide robust protection, featuring a thick outer layer that safeguards your wiring.

With so many options available, electricians often classify cable conduits based on their wall thickness, the type of material used, and their mechanical stiffness. This classification helps in quickly identifying the most suitable conduit for a specific application.

All cable conduits should meet national electricity requirements before installation to ensure they are compatible with your wiring system. Most conduit materials are chosen for their corrosion resistance, mechanical protection, and overall cost-effectiveness of the installation process, which includes both labour and material expenses.

A significant advantage of using cable conduits is that they reduce the need for additional electrical components, such as electrical boxes. For instance, opting for a metal conduit allows you to perform the function of a grounding wire without needing a separate component.

What Is the Best External Cable Conduit?

As mentioned earlier, electrical external conduits come in varying options, sizes, and styles. While this variety makes it easy to find your ideal conduit, it can also make narrowing down your choices challenging. If you’re seeking high-quality cable conduit systems, look no further than Meteor Electrical.

At Meteor Electrical, you can browse through a wide variety of cable management systems, including plastic, metal, and flexible cable conduits. These options are available in numerous sizes to fit any specification.

Our galvanised conduits feature a tough exterior that maintains the integrity of your wiring, keeping it safe from multiple hazards. This ensures that your cables remain functional for an extended period. If you prefer a lighter

cable management system, opt for our plastic trunking solutions.

We offer highly durable plastic trunking from Cablecraft to ensure quality in every installation. These conduits come from Cablecraft’s Betaflex range which offers more flexibility with your cable management.

Designed with corrugated polypropylene material, Cablecraft’s conduits are easy to manoeuvre and fit into any location seamlessly. This material is halogen-free and self-extinguishing, providing added benefits to reduce any chance of electrical fires. Due to this high-grade construction, Cablecraft’s conduits are ideal for commercial and industrial spaces.

What Are Conduit Fittings?

Conduit fittings are the unsung heroes of your electrical system, ensuring everything stays in place and functions smoothly. Available in a variety of sizes, shapes, and materials, these fittings are tailored to meet your specific needs. At their core, fittings connect conduit ends to electrical devices, enclosures, or boxes, establishing a secure and reliable electrical pathway.

But that's not all. Fittings like clips and clamps play a pivotal role in providing additional support, keeping your conduits stable and secure. Selecting the right type of fitting is essential, especially when your system is exposed to vapours, moisture, or other hazardous conditions. Properly fitting conduits externally is even more critical to ensure longevity and performance.

Let’s dive into some of the most important conduit fittings you should consider for your setup.

Conduit Bodies

Conduit bodies are like the junction points in your electrical system. With a tubular structure and openings at both ends, they allow for easy placement and connection of conduits. Available in various sizes and designs, these fittings facilitate seamless bends and connections, ensuring your conduit system flows effortlessly. Each type of conduit body is labeled for easy identification, helping you choose the right one for your specific needs.

Conduit Clips

Long runs of conduits and tubing can sag or break without proper support. This is where conduit clips and clamps come into play. Mounted on walls or ceilings with bolts or screws, these clips keep your conduits firmly in place. It’s crucial to refer to regulatory and safety codes to determine the correct size and dimension for your conduit fittings. Proper installation of conduit clips not only supports the conduits but also ensures compliance with safety standards.

Conduit Couplings

When you need to create a seamless network by combining multiple conduits, conduit couplings are indispensable. While PVC tubing can be linked without a coupling using a belled end, couplings are still necessary in sections where conduits are cut. Available in various sizes and some featuring internal threading, conduit couplings provide a secure and efficient way to extend your conduit system without compromising on integrity.

Finding the Best Conduit Fittings

Once you’ve selected the perfect conduit, the next step is to find the appropriate fittings to complete your system. At Meteor Electrical, we offer a comprehensive range of conduit fittings designed to integrate seamlessly with your conduits, ensuring fluid connectivity throughout your wiring system.

A well-stocked supply of conduit clips is essential for any conduit system. Our partnership with brands like Unicrimp brings you a range of high-quality conduit clips, including white cable clips suitable for 22-26mm round fixtures. Made from high-grade polyethylene, these clips provide excellent flexibility in low temperatures, protecting your wiring from potential damage.

Unicrimp’s nail-in clips keep your wiring organised and secure, safeguarding the cable’s coating from hazards. Available in various sizes, these clips are versatile enough to fit any installation. The 20mm clips, for instance, are perfect for multiple wiring systems, offering both convenience and efficiency. These clips securely attach pipes and electrical or cable wiring to vertical and horizontal beams, ensuring your conduits are safely mounted to walls or ceilings.

Ceiling conduit clips, supported by overhead beams, are ideal for both indoor and outdoor use. Their straightforward installation process means you don’t need specialised mechanical skills—simply screw the clips to a stable surface, and you're good to go. Unicrimp’s cable clips come in white and feature premium steel nails that prevent snapping and reduce the risk of bending your wires, ensuring long-lasting support for your conduits.

What Are Cable Conduits Used For?

Cable conduits do more than just store wiring and cables—they offer a range of benefits that enhance the functionality and safety of your electrical system. Here are some key uses of cable conduits:

• Meet Codes and Regulations: In most cases, conduits are required by building safety standards and codes. Adhering to these regulations is crucial for new constructions and necessary when replacing old, worn-out conduits to ensure compliance and safety. For more information on electrical codes, you can visit the National Fire Protection Association (NFPA).

• Versatility in Design: Cable conduits provide the flexibility to maneuver wiring into any configuration or location, meeting diverse electrical needs without compromising on safety or aesthetics.

• Protect Wiring from Damage: Conduits offer comprehensive protection against moisture, fire, chemicals, impact, and other hazards. While wires and cables typically have their own insulation, conduits add an extra layer of defense, significantly enhancing the overall protection of your electrical system.

• Eliminate Interference: By reducing electromagnetic interference, cable conduits help ensure that your cables and wiring perform optimally, maintaining signal integrity and preventing disruptions.

• Keep Wiring Organised: Managing a multitude of wires and cables can be challenging. Conduits help keep everything organised, preventing disorganised wiring that can damage the outer sheathing of your components. Organised wiring not only looks cleaner but also simplifies installation, maintenance, and future upgrades.

Installation Tips for External Cable Conduits

Proper installation of external cable conduits is crucial to ensure maximum protection and longevity of your wiring system. Here are some tips to help you get started:

1. Plan Your Route: Before installation, plan the route of your conduits carefully. Avoid areas prone to physical damage and ensure easy access for future maintenance.

2. Choose the Right Conduit: Select a conduit type that matches your environmental conditions and cable requirements. Consider factors like weather exposure, potential physical impacts, and the presence of corrosive substances.

3. Secure Properly: Use appropriate fittings and clamps to secure the conduits firmly. This prevents movement that could damage the cables inside.

4. Ensure Proper Sealing: For outdoor installations, ensure that all fittings are watertight to prevent moisture ingress, which can lead to cable degradation.

5. Comply with Standards: Adhere to national electrical codes and standards to ensure safety and compliance. Refer to resources like the National Electrical Code (NEC) for guidelines.

6. Use Protective Accessories: Consider using additional protective accessories like cable ties and brackets to keep the conduits organised and secure.

7. Regular Inspection: Periodically inspect your conduit system for signs of wear, damage, or loosening fittings. Prompt maintenance can prevent larger issues down the line.

Credit: The Jacks of All Trades

Benefits of Using External Cable Conduits

Investing in external cable conduits offers numerous benefits, including:

• Enhanced Protection: Conduits shield cables from environmental hazards, physical damage, and chemical exposure.

• Improved Safety: By reducing the risk of electrical fires and shorts, conduits enhance overall safety.

• Ease of Maintenance: Organised cabling within conduits makes it easier to locate and repair issues without extensive downtime.

• Aesthetic Appeal: Conduits provide a clean and organised appearance, especially in visible areas.

• Compliance: Using conduits helps meet regulatory standards and building codes for electrical installations.

Choosing the Right Conduit Material

Selecting the appropriate conduit material is essential for the effectiveness and longevity of your cable management system. Here’s a quick overview of common materials:

• Metallic (Steel or Aluminium): Offers robust protection against physical damage and is suitable for high-risk environments.

• PVC: Lightweight, flexible, and corrosion-resistant, ideal for general outdoor use.

• Polyamide: Provides excellent resistance to chemicals and flames, suitable for demanding installations.

• Fiber and Fired Clay: Specialised materials used in specific applications where unique properties are required.

Conclusion: Trust Meteor Electrical for Your Conduit Needs

Incorporating the right conduit fittings and cable conduits into your electrical system is essential for ensuring safety, longevity, and optimal performance. Whether you're embarking on a new installation or upgrading an existing system, the right components can make all the difference.

At Meteor Electrical, we are dedicated to providing top-tier cable management solutions tailored to your specific needs. Our extensive selection of conduit fittings and cable conduits ensures that you have the best tools to create a secure and efficient electrical infrastructure. From durable metallic conduits to flexible PVC options, we have everything you need to protect and organize your wiring effectively.

Choose Meteor Electrical for reliable, high-quality products and expert guidance. Let us help you safeguard your electrical systems with our comprehensive range of external cable conduits and fittings. Visit our website today or contact our knowledgeable team to find the perfect solutions for your projects. With Meteor Electrical, your cables are always in safe hands.

Frequently Asked Questions (FAQs)

1. What is an external cable conduit and why is it important?

External cable conduits are protective tubes designed to house and safeguard electrical cables installed outdoors. They shield cables from environmental hazards such as moisture, UV rays, physical impacts, and chemicals, ensuring the longevity and safety of your electrical system.

2. Which type of conduit is best suited for outdoor installations?

For outdoor installations, Rigid Metal Conduit (RMC) and Non-Metallic Liquid-Tight Flexible Conduit (NLFC) are excellent choices. RMCs offer robust protection against physical damage, while NLFCs provide flexibility and watertight sealing, making them ideal for varying outdoor conditions.

3. Can I install external cable conduits myself, or should I hire a professional?

While some conduit installations can be handled as DIY projects, it’s recommended to hire a licensed electrician for external cable conduit installations. Professionals ensure compliance with local electrical codes and safety standards, reducing the risk of errors and enhancing the reliability of your electrical system.

4. How do I choose the right conduit fittings for my installation?

Selecting the right conduit fittings depends on factors like the type of conduit, environmental conditions, and specific application requirements. Essential fittings include conduit bodies for junction points, conduit clips for secure mounting, and conduit couplings for extending conduit runs. At Meteor Electrical, we offer a wide range of high-quality fittings to meet diverse installation needs.

5. How can I maintain my external cable conduits to ensure their longevity?

Regular maintenance is key to extending the life of your external cable conduits. This includes:

◦ Inspecting conduits periodically for signs of wear, damage, or moisture ingress.

◦ Securing loose fittings and ensuring all clips and clamps are tight.

◦ Cleaning conduits to remove debris and prevent buildup.

◦ Repairing any damaged sections promptly to avoid further issues.