Mastering Electrical Conduit Installation: A Comprehensive Guide

Mastering Electrical Conduit Installation: A Comprehensive Guide

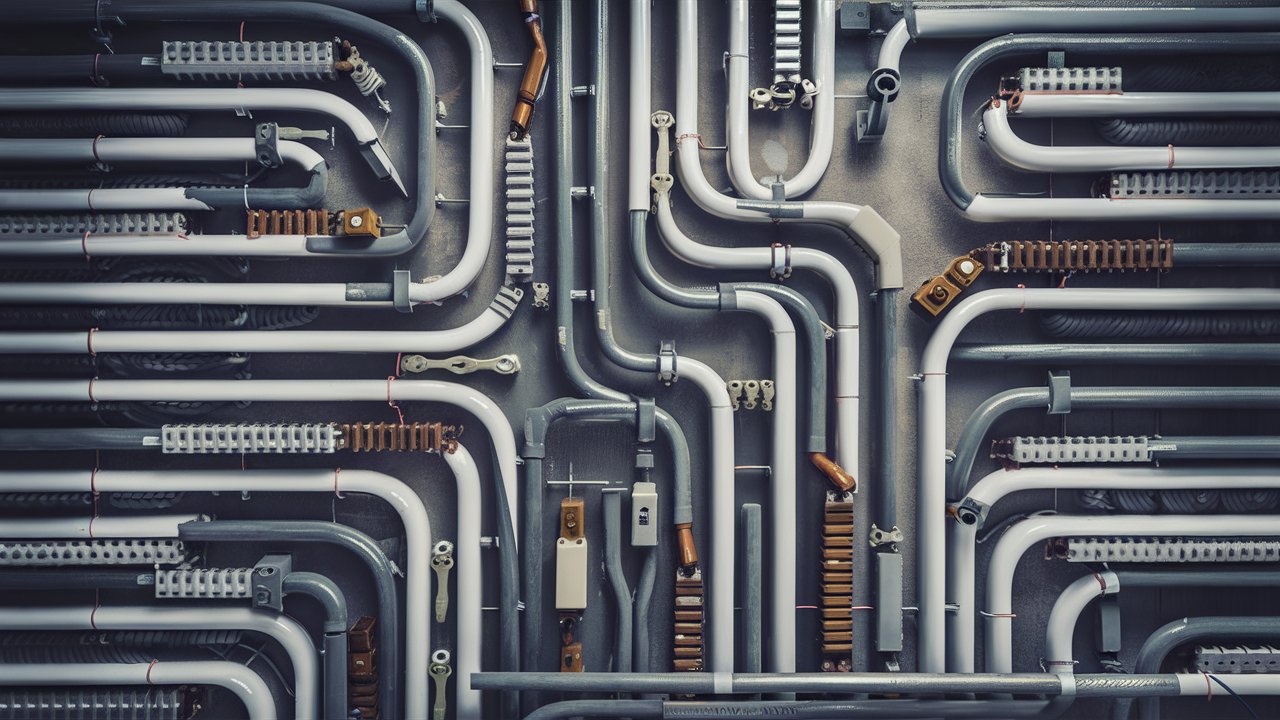

Electrical conduits are indispensable in safeguarding and organising electrical wiring in homes, offices, and industrial settings. Whether you're a seasoned electrician or a homeowner embarking on a DIY project, understanding the nuances of conduit installation is crucial for ensuring safety and compliance with regulations. This comprehensive guide is tailored for audiences in the UK and Ireland, offering step-by-step instructions and essential tips to streamline your conduit installation process.

Understanding Electrical Conduits

Electrical conduits are tubing systems designed to protect and route electrical wiring, shielding them from physical damage, moisture, and chemical vapours (Electrical Safety First). This prolongs the lifespan of electrical systems and reduces the risk of hazards. Conduits come in various materials, such as PVC, galvanised steel, and flexible metal, each chosen based on specific application requirements (The IET).

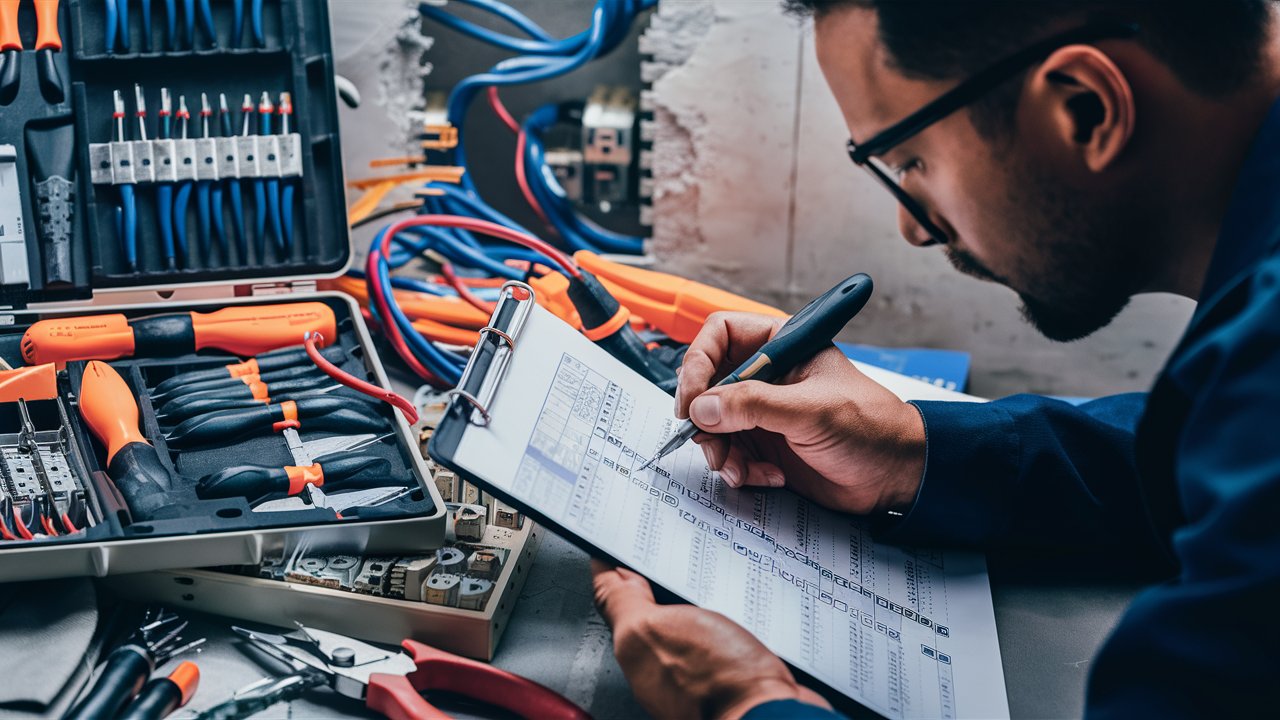

Tools and Materials Required

Before starting your conduit installation, gather the following tools and materials:

- Conduit: Select the appropriate type (PVC, steel, or flexible) and size for your installation needs.

- Conduit Bender: Essential for creating bends and turns in rigid conduits.

- Fish Tape or Draw Wire: Facilitates pulling wires through the conduit.

- Conduit Cutter: Used for precise cutting of conduits to desired lengths.

- Fasteners and Connectors: Ensure secure attachment of conduits to surfaces and facilitate junctions.

- Marker or Pencil, Level, and Measuring Tape: Aid in marking conduit paths, ensuring accurate measurements and alignment during installation.

Step-by-Step Guide to Conduit Installation

1. Planning and Preparation

- Evaluate the Installation Area: Start by assessing the route for your conduit installation. Consider accessibility and choose the shortest, most efficient paths between electrical outlets. This saves materials and ensures a cleaner, more professional look (Wickes).

- Review Regulations: Understanding local building codes and regulations is crucial. Familiarise yourself with these guidelines to ensure your installation meets all safety and compliance standards (Gov. uk).

2. Marking and Measuring

- Trace the Conduit Path: Use a marker or pencil to outline where your conduits will be placed. Accurate marking and measuring are essential for a smooth installation process, so take your time to ensure everything is perfectly aligned (DIY Doctor).

3. Installing Mounting Hardware

- Secure Conduit Straps: Attach conduit straps or clamps along the mounting surface at regular intervals. This strongly supports the conduits, preventing sagging or movement over time (Screwfix).

4. Cutting and Bending Conduit

- Measure and Cut: Measure your conduit lengths carefully and use a conduit cutter for precise trimming. Proper measurements and clean cuts are vital to avoid wastage and ensure a perfect fit.

- Bend the Conduit: Use a conduit bender to create smooth bends and turns. This is especially important for navigating corners or obstacles while maintaining the integrity of the conduit (B&Q).

5. Connecting and Securing Conduits

- Join Conduit Sections: Connect the conduit sections using appropriate connectors to create a continuous, protected path for your wiring. This step is crucial for maintaining the electrical integrity of the installation.

- Secure the Placement: Fasten the connected conduits to the mounting hardware with suitable fasteners, ensuring they remain stable and aligned (Toolstation).

6. Pulling Wires Through Conduit

- Prepare and Pull Wires: Attach your wires to a fish tape or draw wire and carefully thread them through the conduit. Take care to avoid damaging the wires during this process to maintain their functionality and safety (Homebase).

7. Sealing and Final Checks

- Seal Conduit Ends: Use suitable fittings or caps to seal the ends of the conduits, preventing moisture or debris from entering. This step is essential for protecting the wiring inside.

- Inspect the Installation: Conduct a thorough inspection of the entire conduit system. Check for loose connections, ensure proper fastening, and verify that wires are correctly routed. This final check helps to provide a safe and reliable installation (Checkatrade).

Learn more about working with conduits here!

Credit: Electrician U

Benefits of Electrical Conduits

Electrical conduits offer numerous advantages that make them an essential component in both residential and commercial electrical installations:

Enhanced Safety

Conduits protect wires from physical damage, moisture, and chemicals, significantly reducing the risk of electrical shocks or fires (Electrical Safety First). This protection is crucial in high-traffic areas or environments exposed to harsh conditions.

Durability

By shielding wiring from environmental factors and mechanical stress, conduits extend the lifespan of your electrical systems. This added layer of protection ensures that your wiring remains intact and functional for years, even in demanding conditions.

Organised Wiring

Conduits facilitate neat and organised wiring layouts. This not only improves the aesthetic appeal of your installation but also simplifies maintenance and troubleshooting tasks (The IET). Clear and accessible wiring paths make it easier to identify and fix issues quickly.

Compliance

Using conduits ensures that your installations meet regulatory standards and building codes, which is essential for safety and legal compliance (Gov. UK). Adhering to these regulations helps prevent costly fines and ensures that your electrical work is up to standard.

Versatility

Conduits come in various materials and sizes, making them suitable for a wide range of applications. Whether you need to install wiring in a residential home, a commercial building, or an industrial facility, there is a conduit type that fits your specific needs.

Ease of Upgrades and Expansion

When future upgrades or expansions are required, conduits make it easier to add or replace wiring without the need for extensive demolition or reconstruction. This flexibility is invaluable in environments where technology and electrical needs frequently change.

By integrating these benefits into your electrical installations, you can ensure a safer, more durable, and efficient wiring system that meets both current and future needs.

Tips for Successful Conduit Installation

Achieving a successful conduit installation involves more than just following basic steps. Here are some expert tips to ensure your project is smooth, efficient, and up to the highest standards:

Plan Strategically

Thorough planning minimises installation time and optimises the conduit layout for maximum efficiency (DIY Doctor). Map out your installation route carefully, considering factors such as accessibility, the shortest paths, and potential obstacles.

Utilise Quality Tools

Invest in high-quality tools for precise conduit cutting, bending, and securing. Using reliable tools not only makes the job easier but also ensures professional results and reduces the risk of mistakes.

Adhere to Regulations

Always follow local codes and standards to ensure your installations are safe and legally compliant (Checkatrade). Staying up-to-date with regulations helps prevent potential legal issues and ensures the safety of your electrical system.

Regular Maintenance

Inspect conduits regularly for signs of wear, damage, or loose connections (The IET). Regular maintenance helps maintain system integrity and prevents minor issues from becoming major problems.

Label Everything

Clearly label all conduits and wiring paths. Proper labelling helps in future troubleshooting and maintenance, allowing for quick identification of circuits and wiring paths without confusion.

Leave Room for Expansion

Plan your conduit installation with future upgrades in mind. Leave some space within the conduits for additional wires or cables, and consider potential expansions or changes in your electrical system. This foresight can save time and money when modifications are needed.

Secure Conduits Properly

Ensure that all conduits are securely fastened using the appropriate hardware. Properly secured conduits prevent movement and reduce wear and tear on the wiring inside, enhancing the overall durability and safety of the installation.

By incorporating these tips into your conduit installation process, you can achieve a safer, more efficient, and future-proof electrical system.

Explore High-Quality Conduits and Accessories at Meteor Electrical

At Meteor Electrical, we offer a diverse range of high-quality conduits to suit various applications:

- Metal Conduits: Ideal for heavy-duty applications where robustness and durability are paramount. Our galvanised steel conduits provide excellent protection against mechanical impact and environmental elements.

- Plastic Conduits: Lightweight and versatile, PVC conduits are suitable for indoor and outdoor installations. They offer exceptional resistance to corrosion and are easy to install.

- Flexible Conduits: Designed for applications requiring flexibility, such as installations around tight corners or in areas with vibration. Flexible conduits ensure ease of handling without compromising on protection.

Conduit Accessories

In addition to our comprehensive range of conduits, Meteor Electrical also stocks a variety of accessories to facilitate seamless installation and maintenance:

- Connectors and Couplings: Securely join conduit sections and facilitate transitions between different conduit types.

- Conduit Fittings: Includes elbows, connectors, adapters, and bushings to accommodate bends and changes in direction.

- Fasteners and Clamps: Ensure secure mounting of conduits to walls, ceilings, or floors with our quality fasteners and clamps.

Final Takeaway

Mastering electrical conduit installation requires meticulous planning, precise execution, and adherence to safety protocols. Whether upgrading your home's electrical system or undertaking a commercial project, following these steps will help you establish a robust and secure conduit infrastructure.

Meteor Electrical offers a comprehensive range of high-quality products and expert advice for all your electrical conduit needs. Contact us today to discover how we can support your electrical projects with our extensive expertise and superior product offerings.

A well-installed conduit system not only protects your electrical wiring but also enhances overall safety and efficiency. Stay informed, stay safe, and enjoy the benefits of a professionally installed electrical conduit system.

FAQ: Electrical Conduit Installation

Q: What is the purpose of electrical conduits?

Electrical conduits protect and organise electrical wiring, shielding it from physical damage, moisture, and chemicals, thus enhancing safety and durability.

Q: What types of electrical conduits are available?

Common types include PVC, galvanised steel, and flexible metal conduits, each suited for different applications and environments.

Q: How do I choose the right conduit size?

The conduit size depends on the number and size of wires you need to run through it. Refer to local electrical codes and standards for specific requirements.

Q: Can I bend PVC conduit?

Yes, PVC conduit can be bent using a heat gun or a conduit bender designed for PVC to create smooth bends and navigate corners.

Q: How often should conduit straps be placed?

Conduit straps should typically be placed every 3-4 feet and within 1 foot of each outlet box, junction box, or fitting.

Q: Do I need to use special tools to cut conduits?

Yes, using a conduit cutter ensures clean, precise cuts. For metal conduits, you might also need a hacksaw or a power saw.

Q: Is it necessary to seal the ends of conduits?

Yes, sealing the ends with appropriate fittings or caps prevents moisture, dust, and debris from entering the conduits, protecting the wires inside.

Q: How do I pull wires through a conduit?

Use a fish tape or draw wire to thread wires through the conduit. Attach the wires securely to the fish tape and carefully pull them through.

Q: Can electrical conduits be used outdoors?

Yes, certain types of conduits like PVC and galvanised steel are suitable for outdoor use due to their resistance to corrosion and weather conditions.

Q: Are there any regulations for installing electrical conduits?

Yes, always follow local building codes and electrical standards to ensure safety and compliance with regulations.

Q: Can I install electrical conduits myself?

If you have the necessary knowledge and tools, you can install conduits yourself. However, for complex installations, it’s best to consult a professional electrician.