Outdoor Cable Conduit: The Complete Guide for Safe, Compliant Installs

Outdoor Cable Conduit: The Complete Guide for Safe, Compliant Installs

Outdoor electrical wiring is only as reliable as the conduit that protects it. Weather, UV exposure, corrosion, and impact can quickly damage cables unless they are housed in a durable, standards compliant outdoor electrical conduit designed for external environments.

This guide explains outdoor cable conduit types, UK standards such as BS 7671, selection criteria and installation tips, so your next install is safer, neater, and built to last. For further details on outdoor electrical safety standards, check out Electrical Safety First's guide or visit NFPA for more industry-related safety insights.

What Is an Electrical Cable Conduit?

An electrical conduit is a protective tubing system, metallic or non metallic, used to route and shield electrical wiring from mechanical damage, moisture, dust, and UV exposure while simplifying maintenance and upgrades. In UK practice, conduits are specified and installed to comply with BS 7671 requirements for selection and erection of wiring systems, with special attention to weatherproof cable conduit selection where rain and condensation are present.

Key benefits:

- Mechanical protection in areas exposed to impact, abrasion, or garden and vehicular activity outdoors.

- Environmental protection from rain, condensation, sunlight, and corrosive atmospheres with UV resistant conduit where required.

- Easier cable management, future pulls, and selective replacement without excavation or structural damage.

How to Choose an Outdoor Conduit?

Selecting the right outdoor cable conduit is about matching material, rating, and installation method to site risks and standards. Use these criteria to shortlist the best option for durability, compliance, and total cost of ownership.

Environment and location

- Above ground: Prioritise UV resistance, impact strength, sealing, and corrosion protection. Use UV resistant conduit in sunny exposures and weatherproof glands and couplers to maintain ingress protection.

- Underground: Follow best practice for underground cable ducting including depth, marking tape or covers, and mechanical protection. Choose smooth bore ducting that eases pulls and supports compliant backfill and compaction.

Installation method and complexity

- Rigid metallic systems need accurate cutting, threading, and bonding with listed IP rated conduit fittings. Flexible systems simplify routes with tight bends but still require properly rated terminations to keep moisture out.

- Plan draw in points, inspection boxes, and pull lengths using recognised conduit fill and pull calculations to reduce friction and avoid conductor damage.

Durability and material fit

- High risk or exposed sites: Rigid Metal Conduit provides top tier impact resistance and suits harsh conditions with protective coatings and corrosion control.

- Corrosive and condensing areas: PVC or PVC coated systems resist rust. Confirm temperature rating and flame performance, and specify weatherproof cable conduit with sealed joints.

Compliance and standards

- Follow BS 7671 for selection and erection, burial and marking, and special locations. Align product selection with manufacturer data sheets and local authority requirements.

- Verify fittings are system matched, correctly listed for the material type, and marked for use outdoors and in wet locations.

Budget vs lifecycle

- Metallic conduits can cost more upfront but deliver superior longevity where impacts and vandal risks are likely. Non metallic conduits lower installation time and eliminate corrosion concerns, which can reduce lifecycle costs in many residential gardens and light commercial sites.

Best Outdoor Cable Conduit Types

Electrical Metallic Conduit EMT

- What it is: An Electrical Metallic Conduit (EMT) Lightweight galvanised steel conduit common in residential and light commercial work.

- Outdoor fit: Usable outdoors when installed with weatherproof and watertight connectors. Avoid severe corrosion zones or high impact areas unless additional protection is added.

- Pros: Clean bends, neat finishes, abundant fittings.

- Cons: Thinner wall than RMC and less robust where heavy impact is possible.

Rigid Metal Conduit RMC

- What it is: Heavy wall steel or aluminium with excellent mechanical protection and broad environmental resilience.

- Outdoor fit: Ideal for exposed runs, structures, parking areas, and industrial sites where impact or vandalism is a concern.

- Pros: Highest mechanical strength and long service life when combined with appropriate coatings.

- Cons: Higher cost and installation effort due to weight and threading.

Non Metallic Liquid Tight Flexible Conduit NLFC

- What it is: Flexible conduit with a durable PVC jacket suited to liquid tight routing and complex geometries.

- Outdoor fit: Excellent near HVAC, pools, and plant areas where spray and moisture are present. Pair with liquid tight IP rated conduit fittings to maintain system integrity.

- Pros: Fast installation, corrosion resistant, moisture sealed terminations.

- Cons: Not a substitute for heavy impact protection and must respect bend radius limits.

PVC conduit systems

- What they are: Non metallic conduits and fittings that offer corrosion resistance and low weight for above or below ground use.

- Outdoor fit: Suitable where physical damage risk is low to moderate. Specify UV resistant conduit for sun exposure and confirm ambient temperature limits to avoid heat related degradation.

- Temperature note: Many PVC systems observe ambient limits around 50 to 60 degrees Celsius and may require cable ampacity adjustments so conductor operating temperatures stay within the conduit rating.

For a wide variety of high-quality outdoor cable conduits, visit Meteor Electrical, where you'll find an array of plastic, metal, and flexible cable management systems to suit any project.

Underground Conduit and Burial Best Practice

- Depth: As a general guide for low voltage in ordinary ground, many practitioners adopt around 0.5 m cover where no special rules apply. Deeper installation is typical in agricultural land, caravan parks, and roadways according to IET guidance and local rules.

- Marking: Use marker tape or protective covers to flag routes and reduce accidental strikes during future works.

- Method: Use smooth bore underground cable ducting for easier pulls. Bed with sand or fine granular material, avoid sharp stones, and reinstate with compacted layers that protect the route over time.

Standards and Compliance: BS 7671 Highlights

- UK benchmark: BS 7671 governs electrical installations. Confirm conduit selection, routing, and burial practices align with the latest amendment and any local distribution network operator guidance.

- Buried services: Observe location marking, depth, and protective measures including durable warning systems and mechanical protection where required.

- Temperature and materials: Respect equipment temperature limits. PVC systems must be matched with cable insulation ratings and may require derating where multiple current carrying conductors share a run.

- Reference methods and sizing: Apply recognised conduit fill and cable factors to size systems. Avoid overfilling which elevates operating temperatures and raises pulling tension.

What Are the Different Types of Outdoor Cable Conduits?

Not all cable conduits are the same, especially when it comes to outdoor applications. Here’s a look at some of the most popular types:

- EMTs (Electrical Metallic Conduits): Electrical metallic conduits are rigid but can be bent with tools to suit your installation needs. They offer flexibility for indoor and outdoor use but require waterproofing for external applications.

- RMCs (Rigid Metal Conduits): Made from tough, thick materials like stainless steel or aluminium, RMCs provide the highest level of protection and are ideal for outdoor installations exposed to physical damage.

- NLFC (Non-Metallic Liquid-Tight Flexible Conduits): This conduit is best for moisture-heavy environments. Its flame-resistant properties and durability make it suitable for demanding outdoor applications.

- PVC Conduits: Lightweight and easy to maneuver, PVC conduits are ideal for outdoor installations in areas with minimal physical damage. However, they may not be suitable for high-temperature areas.

At Meteor Electrical, you can explore an extensive range of galvanised conduits and PVC options. Whether you're looking for lightweight plastic trunking or heavy-duty metal conduits, Meteor Electrical offers products designed to meet the most demanding requirements.

Source - Ledes Group

How To Run Cables In Conduits Outdoors?

Use proven pulling methods and plan routes for minimal stress and efficient maintenance. Select lubricants compatible with cable jackets and conduit materials, and stage long pulls with intermediate boxes where possible.

- String method: Best for short, straight runs. Push a rod with string attached, tie to the cable at the far end, then pull back through the conduit.

- Conduit piston mouse: Use a vacuum to draw a line through bends and shorter complex runs, then pull in the cable with a draw rope.

- Fish tape: Best for long runs. Feed tape, attach conductors, apply lubricant as needed, then pull steadily while monitoring tension and bend counts.

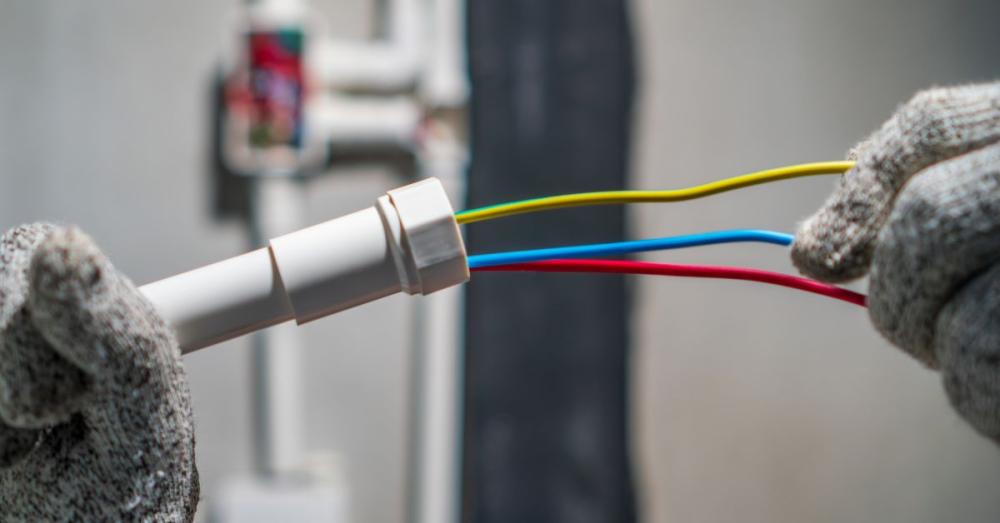

Fittings and terminations

- Always use system matched, listed fittings such as couplings, adapters, and glands that are rated for wet locations. Maintain enclosure ratings by using gaskets and seals on outdoor boxes and junctions.

- Select IP rated conduit fittings appropriate to the environment. For exposed outdoor terminations, IP66 or higher is common, while underground terminations often target IP67 or IP68 depending on submersion risk.

Quick selector guide

- High impact and vehicular exposure: Rigid Metal Conduit with appropriate coatings and listed fittings.

- Damp or wet routes with bends: Non Metallic Liquid Tight Flexible Conduit or PVC with liquid tight fittings. Use metallic alternatives if impact is likely.

- Cost sensitive, low impact areas: PVC conduit specified as UV resistant conduit for sun exposure and installed within temperature limits.

- Neat above ground runs: EMT with weatherproof connectors where corrosion exposure is low and appearance matters.

Installation Tips for Performance and Compliance

- Plan pull points and accessible boxes for long runs and multiple bends to limit pulling tension and simplify maintenance.

- Apply conduit fill and derating rules from BS 7671 and the On Site Guide. Avoid overfilling because it makes pulls harder and raises thermal stress on cables.

- For burial, maintain depth, warning tape or covers, and suitable bedding and backfill. Record as built routes and photograph key waypoints to assist future fault finding.

These are just a few of the key points from the British Electrical Regulations. For a safe and durable installation, electricians should consult the full set of regulations to ensure they are following the best practices.

Where to Buy Outdoor Cable Conduits?

Browse a wide range of outdoor electrical conduit including PVC, galvanised steel, flexible liquid tight options, and underground cable ducting at Meteor Electrical. Find matched IP rated conduit fittings, junction boxes, and weatherproof enclosures for domestic, commercial, and industrial projects.

Conclusion

The right outdoor cable conduit turns a vulnerable cable run into a durable asset that resists impact, water, UV, and corrosion while remaining compliant with BS 7671. Match the conduit type to site risks, size and install it using recognised methods, and finish with correctly rated weatherproof and IP rated conduit fittings for long service life.

For compliant, high quality materials, shop outdoor electrical conduit, trunking, underground cable ducting, cable management systems and weatherproof enclosures at Meteor Electrical.

Power your next project with trusted products and expert support from Meteor Electrical!

FAQs

1) What is the best conduit for outdoor wiring?

The best choice depends on risk and environment. Rigid Metal Conduit suits high impact and exposed weather. Non Metallic Liquid Tight Flexible Conduit or PVC works well in damp areas with multiple bends. EMT can be used outdoors with weatherproof connectors in low corrosion zones.

2) Can PVC conduit be used outside and underground?

Yes. Use UV resistant conduit above ground and install underground cable ducting at appropriate depths with marker tape or covers. Follow BS 7671 guidance for protection, backfill, and current carrying capacity.

3) What depth should outdoor electrical conduit be buried?

A commonly followed practice is about 0.5 m cover for low voltage in ordinary ground where no special rule applies. Agricultural land, caravan sites, and roadways often require deeper installation to meet safety and maintenance needs.

4) Is EMT conduit suitable for outdoor use?

EMT is suitable outdoors when galvanised or coated and paired with weatherproof and watertight connectors. It is not preferred in severe corrosion zones or where frequent mechanical impact is expected.

5) What is the temperature limit for PVC conduit outdoors?

Many PVC systems observe ambient limitations around 50 to 60 degrees Celsius. Ensure cable ampacity is adjusted so conductor temperatures do not exceed conduit limits and verify product specific data sheets.

6) How do I size conduit for multiple cables?

Use recognised conduit fill methods from BS 7671 and the On Site Guide. Sum cable factors, select a conduit with an equal or higher conduit factor, and consider length and bend count to manage pulling tension.

7) Do I need special fittings for outdoor conduit?

Yes. Use system specific, listed IP rated conduit fittings that are approved for outdoor and wet locations. Maintain enclosure IP ratings with gaskets and seals to prevent moisture ingress.

8) What UK standards apply to outdoor cable conduit?

Installations must comply with BS 7671 and applicable IET guidance for burial, selection, erection, and special locations. Always check manufacturer instructions and local rules.