Understanding Electrical Regulations and Standards

When it comes to electrical systems, safety is paramount. Did you know that electrical fires cause over 50,000 fires annually in the United States alone, leading to more than $1.3 billion in property damage each year? Understanding and adhering to electrical regulations and standards is not just a best practice—it’s essential for protecting lives and property.

Electrical regulations and standards are designed to prevent such hazards and ensure that our electrical systems operate safely and efficiently. Whether you're a professional electrician or a DIY enthusiast, grasping these guidelines can make a significant difference.

In this guide, we’ll explore the importance of electrical regulations, break down the key standards you need to know, and provide practical insights to help you stay compliant and safe. Ready to power up your knowledge? Let’s dive in and illuminate the world of electrical safety!

For more detailed statistics and information on electrical safety, check out the National Fire Protection Association (NFPA) and the Electrical Safety Foundation International (ESFI).

Why Electrical Regulations and Standards Matter?

Electrical safety is the general practise of safely handling electrical wiring and equipment. Electricians or other professionals in this field often use these guidelines, but it’s also crucial for everyone to be aware of these hazards.

In our daily lives, we are constantly exposed to electronic items. In today’s modern world, dealing with one electronic device or another is a given. This makes it important to stay safe and cautious at all times. Electrical safety guidelines are vital because they outline exactly what to do in a hazardous situation. Ignoring these rules can lead to serious injuries or even fatal accidents.

Even though we interact with electronics daily, the risks are typically lower compared to those working directly with dangerous electrical systems. Electricians regularly handle these situations and are trained to identify potential hazards and take necessary precautions. However, lack of experience or inadequate training can still lead to serious incidents, including electrocution or death.

If you work in a warehouse or manage one, it’s essential to familiarise yourself and your employees with electrical safety standards. In industrial settings, individuals frequently interact with electrical machinery and power lines. Regular training programs and clear guidelines are crucial to ensure everyone’s safety.

Also Read: Future-Proof Your Home: The Best Electrical Cables for Modern Wiring Needs

Regulations and Standards

In most countries, all electrical installations must comply with multiple sets of regulations, issued by national organisations or accredited private entities. Builders and electricians take these regulations into account when setting up electrical systems. For example, a builder will design a specific electrical network for a household based on the region’s electrical regulations.

These regulations often vary depending on the type of appliance and its voltage. High-voltage equipment comes with its own set of rules, while low-voltage items have different guidelines. This ensures that each type of equipment is installed and maintained properly according to its requirements.

International and UK Standards

Globally, the International Electrotechnical Commission (IEC) provides the IEC 60364 guidelines, which offer a comprehensive framework for electrical installations. These standards are recognised worldwide but may not cover every detail specific to each region.

In the UK, the British Standard (BS) 7671, also known as the IET Wiring Regulations, is the key reference. First established in the 1800s, these regulations have evolved significantly. The latest 18th Edition includes modern requirements like energy efficiency and electric vehicle charging installations. This evolution ensures that the regulations remain relevant and effective in today's technological landscape.

Credit: eFIXX

Understanding Electrical Wiring

If you’re taking on an electrical project, understanding your wiring is crucial. Here’s what you should know:

Basics of Electrical Wiring

Properly identifying and installing the correct electrical wiring is fundamental for any repair or renovation. It’s essential to understand electrical terminology, the materials needed, and any special tools or devices. Familiarity with these aspects will help you follow electrical codes designed to keep your home or workspace safe.

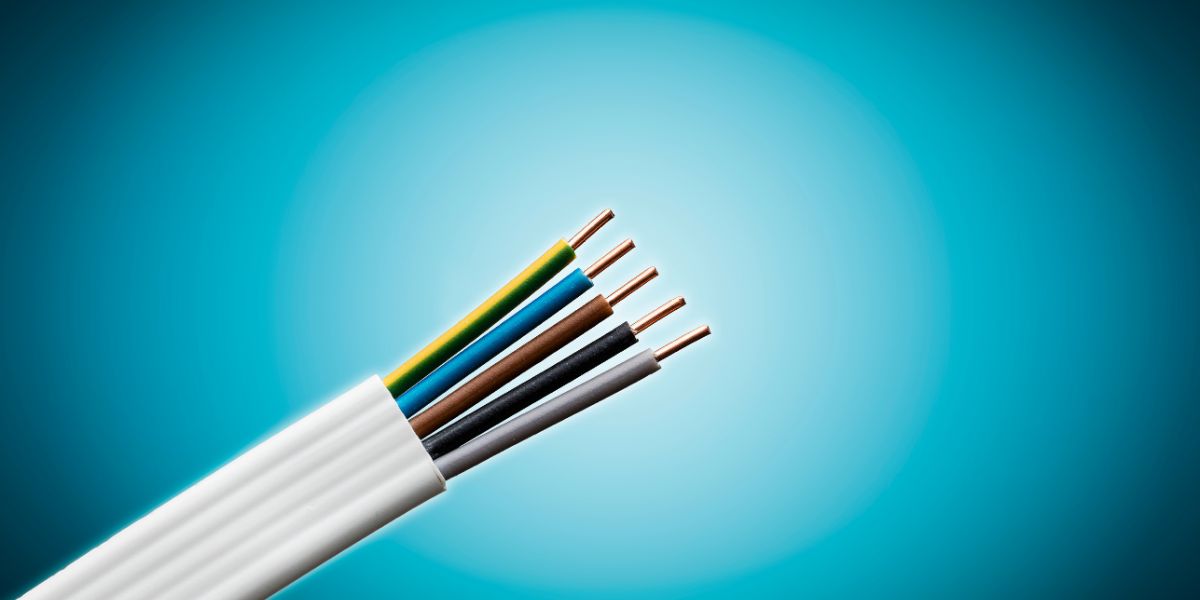

Electrical Wire Colour Coding

One key aspect of working with electrical wiring is understanding colour coding. This system helps identify the purpose of each wire, ensuring correct connections and organised electrical systems.

In the UK, the common wire colours include:

- Green and Yellow for the Earth Wire: Crucial for safety, it directs electrical faults away from you and prevents dangerous situations like electric shocks.

- Brown for the Live Wire: Carries current from the power source to your appliances.

- Blue for the Neutral Wire: Returns current to the main power supply.

Old UK Wire Colours:

You might still encounter older wiring systems with different colours:

- Earth Wire: Green and Yellow (without a sleeve)

- Live Wire: Red

- Neutral Wire: Black

Understanding these colours helps ensure that you handle and repair wiring correctly, avoiding hazardous situations and maintaining an organised electrical system.

Why Did the Wiring Colours Change?

The shift to new wiring colours in the UK, which became mandatory in 2006, aimed to align with European standards and enhance safety. Although the transition started in 2004, many systems were still using the old colours until the government officially outlawed them in April 2006. This change, documented in the BS 7671 guidelines, was part of a broader effort to create a harmonised electrical wiring system across Europe.

While the new colour codes are now the standard, some older buildings still use the previous system. The guidelines stipulate that any new installations after 2006 must adhere to the updated colour scheme, but there’s no requirement to retroactively update existing wiring in older buildings.

What Other Regulations Are There for Electrical Safety?

In addition to electrical regulations concerning installation, several other codes are crucial for ensuring the safety of both workers and electrical systems:

1. Health and Safety Work Standards

These regulations cover occupational health and safety in the UK, protecting employees and the public from potential risks associated with electrical systems. This standard also extends to self-employed individuals, ensuring they are safeguarded against various hazards.

2. Electricity Regulations in the Workplace

These codes focus on the safe handling of electrical devices in the workplace, going beyond installation. They build on the General Health and Safety at Work Act, offering detailed guidance for assessing and minimising risks related to electrical equipment.

3. Management of Health and Safety at Work Regulation

This act requires employers to conduct thorough risk assessments to identify and manage potential health and safety hazards at their workplace. It aims to eliminate or mitigate risks, ensuring a safer working environment.

| Aspect | Details |

|---|---|

| Importance of Regulations | Electrical regulations ensure safety by preventing hazards such as electrical fires, injuries, and fatalities. They help in maintaining safe and efficient electrical systems. |

| International Standards | IEC 60364: Guidelines from the International Electrotechnical Commission providing a framework for electrical installations worldwide. |

| UK Standards | BS 7671 (IET Wiring Regulations): Key reference in the UK for electrical installations. The latest 18th Edition includes modern updates such as energy efficiency and electric vehicle charging. |

| Wiring Color Codes | Current UK Colours: - Green and Yellow: Earth Wire - Brown: Live Wire - Blue: Neutral Wire Old UK Colours: - Green and Yellow: Earth Wire (without a sleeve) - Red: Live Wire - Black: Neutral Wire |

| Reason for Colour Change | The change to new wiring colours in 2006 aimed to align with European standards for safety and consistency. This transition helps harmonise practices across Europe. |

| Health and Safety Work Standards | Regulations covering occupational health and safety in the UK, protecting both employees and the public from electrical hazards. |

| Electricity Regulations in the Workplace | Codes that guide the safe handling of electrical devices at work, building on the General Health and Safety at Work Act. |

| Management of Health and Safety at Work Regulation | Requires thorough risk assessments to manage potential hazards in the workplace, ensuring a safer environment. |

| 18th Edition Training | Components: - Fundamental Principles and Objectives - Terminology Definitions - Overview of Characteristics - Information for Safety |

| Electrical Maintenance Tips | 1. Use the right safety equipment 2. Shut off the power supply 3. Look out for standing water 4. Inspect equipment for visible damage 5. Maintain a schedule for inspections |

Credit: Schneider Electric

What Is 18th Edition Training?

To ensure compliance with the latest standards, the 18th Edition of the BS 7671 codes introduces specialised training for electricians. This training is essential for maintaining safety and reducing costs associated with maintenance and repairs.

Important Components in 18th Edition Training

Here’s what the training covers:

- Fundamental Principles and Objectives: An overview of BS 7671, its objectives, and the importance of adhering to these regulations to ensure safety.

- Terminology Definitions: Clarification of terms, phrases, and acronyms used in the electrical field, essential for understanding and applying the standards correctly.

- Overview of Characteristics: Descriptions and comparisons of different electrical installations, helping electricians differentiate between systems.

- Information for Safety: This section focuses on safety precautions and techniques to minimise risks during installations, including protection against electrical fires, shocks, and explosions.

Completing this training provides a valuable certification and practical knowledge for working safely in the electrical sector.

How to Conduct Proper Electrical Maintenance?

Regular maintenance is key to preventing accidents and ensuring the reliability of electrical systems. Here’s a guide to effective maintenance:

1. Always Use the Right Safety Equipment

Before starting maintenance, ensure you have all necessary safety equipment:

- Hard hat

- Insulated gloves

- Insulated matting

- Safety boots

- Goggles

Additional gear might be required depending on the specific electrical component.

2. Shut Off the Power Supply

Always turn off the power before beginning any inspection or maintenance work to prevent electrical shocks. Inspect the component carefully before handling it to ensure it’s safe to work on.

3. Look Out for Standing Water

Water can cause severe electric shocks when it comes into contact with electrical components. Ensure your work area is dry to avoid accidents. Avoid working in or near puddles or other sources of standing water.

4. Inspect Equipment for Visible Damage

Check for visible damage, such as broken insulation or frayed wiring, before starting maintenance. Avoid using damaged components to reduce the risk of hazards.

5. Maintain a Schedule for Inspections

Regular inspections help identify and fix problems before they escalate. Create a maintenance schedule to stay on top of electrical system checks and avoid costly repairs.

By following these steps, you ensure your electrical maintenance aligns with regulations and keeps your systems safe and efficient.

Conclusion

Understanding and following electrical regulations and standards is crucial for safety and efficiency. Whether dealing with new wiring colours, undergoing 18th Edition training, or performing routine maintenance, staying informed and proactive helps prevent hazards and ensure reliable performance. For the latest guidelines and best practices, consult trusted resources such as the National Fire Protection Association (NFPA) and the Electrical Safety Foundation International (ESFI). Your dedication to safety and compliance not only protects your property but also contributes to a safer environment for everyone.

At Meteor Electrical, we are committed to upholding the highest standards of electrical safety and service excellence. Your dedication to safety and compliance protects your property and contributes to a safer environment for everyone. Trust Meteor Electrical to power your safety and success!

FAQs

1. Why did the UK change its electrical wiring colours?

The UK adopted new wiring colours to align with European standards, enhancing safety and ensuring consistency across the region. This change, mandated from 2006, helps harmonise electrical wiring practices throughout Europe.

2. What are the key regulations for electrical safety?

Key regulations include:

- Health and Safety Work Standards: Protects employees and the public from electrical hazards.

- Electricity Regulations in the Workplace: Focuses on the safe handling of electrical devices.

- Management of Health and Safety at Work Regulation: Requires risk assessments to manage potential hazards.

3. What is covered in the 18th Edition training for electricians?

The 18th Edition training includes:

- Fundamental Principles and Objectives: Overview of BS 7671 and its importance.

- Terminology Definitions: Clarification of key terms and acronyms.

- Overview of Characteristics: Descriptions of different electrical installations.

- Information for Safety: Techniques to minimise risks and enhance safety.

4. How often should electrical systems be maintained?

Electrical systems should be inspected regularly, ideally according to a maintenance schedule. Regular checks help identify and address potential issues before they become serious problems, ensuring ongoing safety and efficiency.

5. What should I do if I encounter standing water near electrical components?

Avoid working in or near standing water, as it poses a serious risk of electrical shock. Ensure your work area is dry and clear of any moisture before beginning maintenance or inspections to maintain safety.