Find the Perfect Gland for Your SWA Cable: A Comprehensive Guide by Meteor Electrical

When it comes to working with Steel Wire Armoured (SWA) cables, choosing the right gland size is not just a matter of preference—it’s essential for ensuring the safety, efficiency, and longevity of your electrical systems. At Meteor Electrical, we understand the importance of getting this choice right, which is why we've created this comprehensive guide to help you select the perfect gland for your SWA cable. Whether you're a professional electrician or a DIY enthusiast, this guide, coupled with our easy-to-use SWA gland size chart, will make the process smoother and simpler.

Let’s dive into the details of choosing the perfect gland and the key factors you should consider!

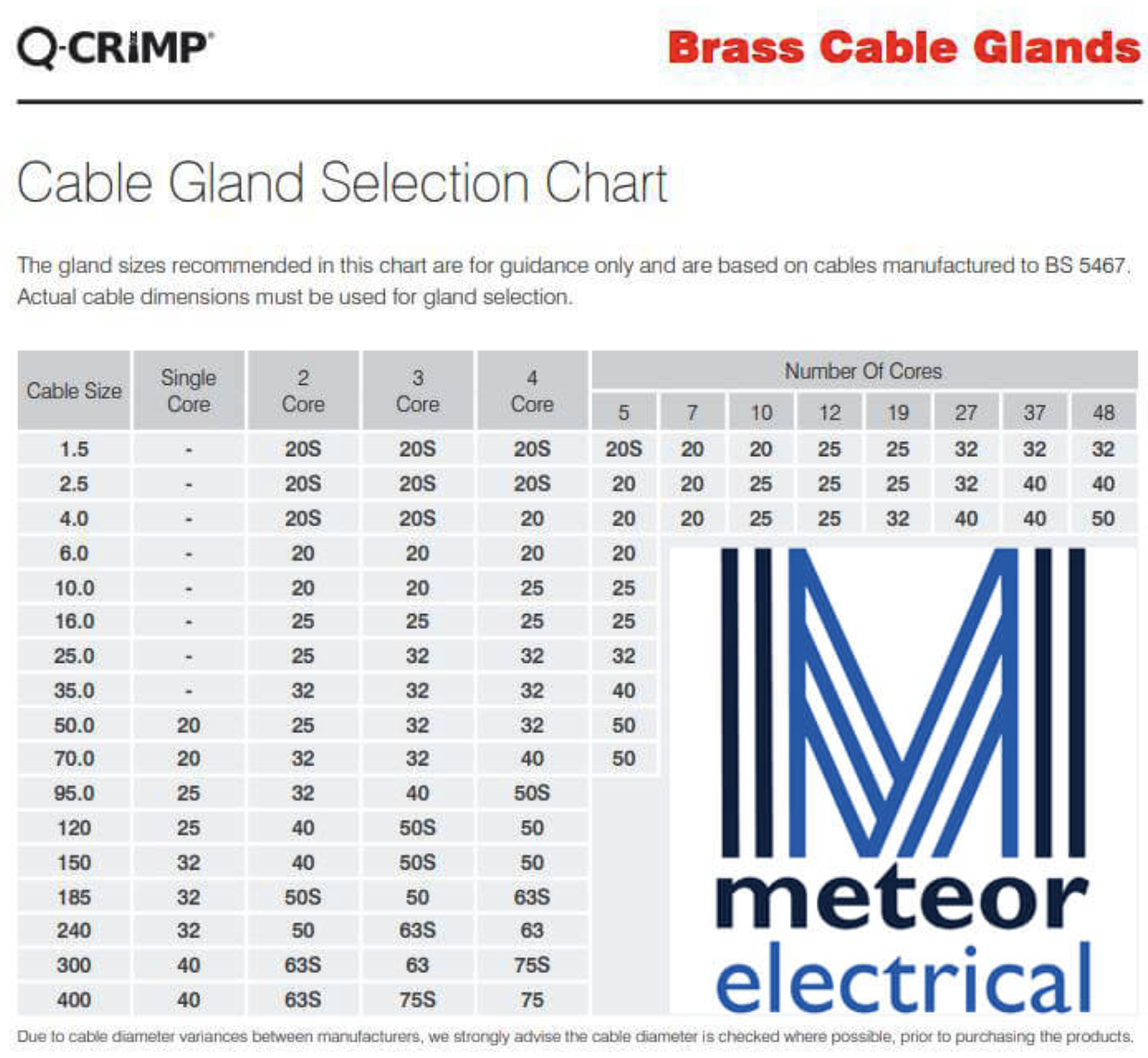

The Ultimate SWA Gland Size Chart

Our SWA gland size chart is your go-to reference for finding the right gland for any SWA cable and its accessories. With a glance, you can quickly determine the perfect fit. No more wasted time guessing or searching—Meteor Electrical’s chart makes your choice easy. Visit our SWA cable gland page to use our convenient filters and quickly find what you need. Here’s a helpful guide to get you started.

Why Use SWA Glands?

SWA glands are indispensable for ensuring the security and functionality of electrical installations and cable management. Here’s why these simple yet effective components are essential in the world of electrical systems:

1. Secure Cable Ends

SWA glands ensure a firm and stable connection by securing the cable ends effectively. This helps in reducing movement and the risk of disconnections, which could otherwise result in electrical failures or damage.

2. Provide Earthing

Effective earthing is crucial for electrical safety. SWA glands help in grounding the electrical system, reducing the risk of electrical shocks and maintaining system integrity. Proper earthing is vital for long-term system reliability (source).

3. Ensure Insulation

The insulation provided by SWA glands is a key defense against electrical faults such as short circuits, safeguarding both the wiring and surrounding equipment from potential damage.

4. Offer Bonding and Strain Relief

SWA glands offer bonding between the cable and equipment, providing strain relief that prevents mechanical wear over time (Fictiv). This ensures the cables remain intact and functional in even the most challenging conditions.

5. Seal Against Environmental Factors

Whether it’s moisture, dust, or chemicals, SWA glands protect cables from a variety of harmful environmental factors. This protection makes SWA glands perfect for use in tough industrial settings or outdoor installations.

6. Versatile Applications

From industrial and commercial settings to outdoor installations, SWA glands are flexible enough to meet the demands of any environment. Their durability ensures reliable performance, regardless of the harshness of the surroundings.

Credit: About the House

Choosing the Right Materials for Your SWA Glands: Durability and Performance

Material selection plays a significant role in the performance of SWA glands. Different materials are suited for various environmental conditions, offering specific benefits for different applications.

Metallic Materials:

- Brass: Known for its mechanical strength and corrosion resistance, brass is ideal for industrial applications.

- Stainless Steel: Its superior resistance to corrosion makes it perfect for harsh environments, especially in marine or chemical industries.

- Aluminium: Lightweight yet robust, aluminium is a great choice for situations where weight is a concern without compromising strength.

Non-Metallic Materials:

- Nylon: Resistant to moisture, chemicals, and wear, nylon is perfect for outdoor and industrial environments.

- PVC: Cost-effective and versatile, PVC is often used in environments where environmental factors are less harsh.

- PTFE (Teflon): With its high-temperature resistance and non-reactivity, PTFE is ideal for specialised applications requiring chemical resistance.

| Material | Characteristics | Best Use |

|---|---|---|

| Brass | Excellent mechanical strength, corrosion-resistant | Ideal for industrial applications where durability is key |

| Stainless Steel | Superior corrosion resistance, highly durable | Suitable for harsh environments like marine or chemical industries |

| Aluminium | Lightweight yet strong, resistant to corrosion | Perfect for applications where weight is a concern but strength is needed |

| Nylon | Resistant to moisture, chemicals, and wear, lightweight | Best for outdoor and industrial applications in moderate conditions |

| PVC | Versatile, cost-effective, resistant to mild environmental factors | Used in less demanding environments where corrosion or harsh chemicals are not a concern |

| PTFE (Teflon) | High-temperature resistance, non-reactive, chemically resistant | Ideal for specialised applications requiring high-temperature resistance and chemical protection |

| Combination | Mix of metallic and non-metallic materials for enhanced durability | Used for demanding environments that require both flexibility and resistance to corrosion, wear, and environmental factors |

Combination Materials:

Some glands are made from a combination of metallic and non-metallic materials, providing the best of both worlds. These glands are built to withstand various environmental factors and provide enhanced durability and flexibility.

Corrosion Resistance

Material selection is crucial in environments exposed to moisture, salt, chemicals, or extreme temperatures. For example, stainless steel glands offer outstanding resistance to seawater corrosion, making them ideal for marine environments.

Credit: GSH Electrical

Understanding How SWA Cable Glands Work

SWA cable glands are designed to ensure the secure operation of armoured cables. These glands consist of various parts including a central enclosure, lock nut, washers, seal, and compression nut. Some advanced models feature dual enclosures or specialised materials like PVC insulation or rubber sealing for added protection.

By effectively sealing cables and providing strain relief, SWA glands help maintain the integrity of your electrical systems, ensuring long-term reliability.

Choosing the Right SWA Gland Size

Selecting the correct gland size is crucial for your installation. Here are the critical considerations to ensure you choose the right fit:

- Cable Diameter: Measure the diameter of the inner bedding and lead covering.

- Construction Size: Assess the overall construction size of the cable.

- Short Circuit Fault Rating: Ensure the gland can handle the short-circuit fault rating of your cable.

- Type and Size of Armour Braid: Identify the type and size of the armour braid.

To avoid any confusion, ask yourself these simple questions:

- Is the wire hole diameter sufficient to fit all cables?

- Does the cable diameter match your needs?

- Does the gland’s pressure rating meet your requirements?

- Is the mounting hole diameter adequate?

- Are stopper plugs needed?

Using Meteor Electrical’s SWA Gland Size Chart

Meteor Electrical’s SWA gland size chart is your all-in-one resource for finding the perfect gland size. It covers cables from 1-core to 48-core configurations, making it versatile for different electrical setups. Whether your SWA cable diameter is 50mm or 100mm, our chart makes choosing the right size easy. Check out the full size chart and shop now.

Specialised SWA Glands: 20S and M20 Variations

Meteor Electrical also offers specialised glands, such as:

- 20S SWA Cable Gland: Designed for all types of armoured cables, providing environmental sealing and mechanical retention.

- M20 vs M20s Glands: M20 glands feature silica gel for high-temperature resistance, making them ideal for use in advanced energy systems that need robust protection.

Secure Your Connections with Meteor Electrical

At Meteor Electrical, we pride ourselves on offering high-quality SWA glands, cables, and a variety of other electrical products to ensure your installations are safe and efficient. Whether you're working on a residential, commercial, or industrial project, you can count on us to provide the best products for your needs.

Explore our full range of electrical products and secure your connections today with Meteor Electrical.

Conclusion

Choosing the right SWA gland is a key step in ensuring a safe, durable, and efficient electrical installation. By following our guide and utilising our detailed gland size chart, you’ll be able to make the best choice for your project, no matter the scale. At Meteor Electrical, we’re committed to providing high-quality solutions for all your electrical needs. Visit our store now to shop for SWA glands and other essential products!

FAQs

1. What is an SWA cable gland used for?

SWA cable glands are essential for securing the ends of Steel Wire Armoured cables, providing earthing, insulation, and strain relief. They protect cables from environmental factors like moisture and dust, ensuring safe and efficient electrical installations.

2. How do I choose the correct size for an SWA gland?

To choose the right size, measure the diameter of the cable's inner bedding and lead covering, assess the construction size of the cable, and check the short circuit fault rating. Meteor Electrical’s SWA gland size chart can guide you in finding the perfect fit.

3. What materials are SWA glands made from?

SWA glands come in a variety of materials, including brass, stainless steel, aluminium, nylon, PVC, and PTFE. The material you choose depends on your environment and application needs, such as corrosion resistance, temperature tolerance, and mechanical strength.

4. Can I use SWA glands outdoors?

Yes, SWA glands are ideal for outdoor installations as they are designed to withstand harsh environmental conditions. They provide effective sealing against moisture, dust, and chemicals, ensuring long-term durability and performance.

5. Are there different types of SWA glands for various applications?

Yes, there are different types of SWA glands designed for specific uses. For example, 20S glands offer mechanical retention and environmental sealing, while M20 glands, with silica gel, are suited for high-temperature applications. Choose the right type based on your system's requirements.