Steel Conduit for Secure & Reliable Cable Management

Steel conduit is one of the most reliable materials for installation purposes. Metal conduits are commonly used in commercial and industrial sectors. However, there are important things to consider before installing round steel conduits.

Heavy-duty metal cable conduits need careful installation to reduce the risk of hazardous conditions and to ensure that your metal conduit lasts a long time. Here are some important things to consider before installing metal cable conduits.

What Is A Steel Conduit?

A steel conduit is a part of the metal electrical conduit family. A round steel conduit is a steel-based durable encasing material that joins individual electrical wiring conductors in a building or a structure.

Metal electrical conduits are best for protection as they have a thick outer layer that keeps your wiring safe in any circumstance. Metal conduits are also used to protect wires from moisture, chemical vapours and impact. Metal conduits are also used to protect wires from moisture, chemical vapours and impact. Apart from metal conduits, other conduits are made out of plastic, fibre and fired clay.

Round steel conduits are divided by several factors. Electricians classify metal conduits according to their wall thickness, the type of material used and the mechanical stiffness.

All metal conduits should meet the national electricity requirements before installation to ensure that the material works best for your wiring system. Most metal electric conduit materials are chosen for their corrosion resistance, mechanical protection and overall cost of the installation process. This cost includes the labour and material prices.

While metal conduits are the most common form of conduits, wiring regulation for some electrical equipment requires particular types of conduits to be used.

Overall, the main purpose of metal cable conduits is to provide insulation to electric cables for domestic and commercial. These specific metal cable conduits are used to avoid accidents in hazardous areas. A good metal cable conduit should also protect from moisture, UV, and rodent damage. When investing in a conduit system, you might be wondering, what conduit material is better? Steel or PVC? Ultimately, both materials have their advantages and you can't go wrong with either. With Steel conduits, you get a durable, tough conduit that will hold up very well over time.

Shop our selection of 20mm, 25mm, and 32mm conduits. Our full range of metal cable conduit and galvanised conduit fittings across numerous sizes are available for next-day delivery throughout the Republic of Ireland.

You can find round steel conduits in different sizes, and every metal conduit comes with its own set of accessories such as junctions, bends and clamps. Metal cable conduits are also available in various sizes such as C-shapes, T-shapes, and L-shapes to make installation much easier.

Some common applications of round steel conduits include:

- Electrical and communication outlet installation in large open locations.

- Direct encasing in concrete

- Protecting conductors against fire damage

- Providing a high-quality control wiring system

- Protecting sensitive circuits from electromagnetic fields and electromagnetic interference

- Preventing EMF and EMI emission

- Providing submersible and waterproof metal electrical conduit system

What Are The Types Of Round Steel Conduits?

There are several types of electrical conduits. Most electrical conduit metals are divided into two categories - metal and non-metal. Each of these electrical conduit metals has its own advantages and disadvantages. The four types of electrical conduit metals are:

- Rigid metal conduit

- Electrical steel conduit

- Flexible steel conduit

- Intermediate metal conduit

- Liquid-tight flexible metal conduit

These are the most common electrical conduit metals on the market and are used for commercial, industrial and residential purposes. Here’s a closer look at each type of electrical conduit metal.

Rigid Metal Conduit

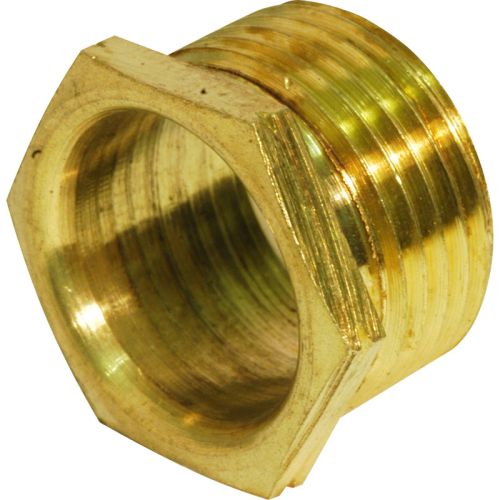

A rigid metal conduit is a thick-walled and threaded conduit. It is usually a stainless steel conduit, or made of coated steel, or aluminium. A rigid metal conduit is connected by screwing connectors to the main tubes.

This conduit provides significant protection from hazardous impacts and other damage. It should be used as a grounding conductor for short runs, but it is best to use a rigid metal conduit with a grounding wire.

Electrical Steel Conduit

An electrical is your best option if you want to install a rigid conduit system. An electrical steel conduit is a thin wall conduit, the commonly used non-flexible conduit. Due to its manufacturing, electrical steel conduits can be applied in many locations.

However, if an area experiences several physical damages, you should not use a steel electrical conduit as it will get damaged very easily and ruin your wiring system. You can use steel electrical conduits as an exposed or concealed wall installation.

You can also use electrical steel conduits on floors and ceilings. Steel electrical conduits’ material allows them to be embedded into concrete, or they can be buried in the ground.

Metal electrical conduits are popular for commercial buildings but should not be used in residential areas. Metal electrical conduits are connected with clamp-style fittings that slide onto the tubing.

This configuration is secured with a set-screw and locked into your desired area. Even though metal electrical conduits provide decent protection for inside cables, they should not be used in hazardous locations (such as power plants) where they might experience severe damage.

Metal electrical conduits are unsuitable for wet areas or places with corrosive fumes and vapours. If you want to use metal electrical conduits in such locations, you must use corrosive-resistant tubing and gasket clamps.

Some electricians avoid using metal electrical conduits in critical areas because the set-screws in the clamps tend to loosen over time. To prevent this loosening, a torque wrench will provide the correct tension to the screws to help them last longer.

What Are The Advantages OF Electrical Steel Conduits?

Electrical steel conduits work well if you require a rigid conduit as this material is much lighter and easier to handle. Electrical steel conduits are easy to cut and ream, making the installation seamless. If you want to put a conduit in complicated positions, you can easily bend steel electrical conduits to fit small diameters and configurations.

Steel electrical conduits are less expensive than other rigid conduits. Since electrical steel conduits have a thin steel material, it’s easy to create circular cross-sections. These conduits also have a corrosion-resistant organic coating that makes electrical steel conduits last a long time.

Flexible Steel Conduit

A flexible steel conduit is used whenever good flexibility is required. Flexible metal conduits are built in such a way that they provide easy movement and vibration of equipment. If you want to place conduits with bends and offsets, you should use flexible steel conduits instead of rigid conduits.

Flexible steel conduits have a ring-like texture that makes it easy to bend them into any configuration. The coating on flexible steel conduits is made from galvanised steel, aluminium, bronze or brass. These coatings keep your flexible metal conduits protected from physical and chemical hazards.

Flexible metal conduit is usually available in diameters between 3/8" and 3"; however, you can also find many large sizes. Flexible metal conduits are made by coiling self-interlocked steel or aluminium strips.

These strips form a hollow tube that wires are pulled through. Flexible metal conduits come in a standard or full wall thickness and a reduced wall thickness. Most manufacturers also create an extra flexible metal conduit for tighter bend radiuses, but these don’t meet electrical safety certifications.

Standard flexible metal conduits are recommended for dry areas where it would be impractical to install steel electrical conduits or other non-flexible conduits. Despite its flexibility, these types of conduits provide enough protection to wirings. Because of its pliability, flexible metal conduit reduces passing motor vibrations to the structure through the conduit.

What Are The Application Of Flexible Metal Conduits?

Flexible metal conduits can be used for lighting fixtures that are above-suspended ceilings. The flexibility gives the wiring movement and allows you to position it in any way you want.

Intermediate Metal Conduit

Intermediate metal conduit is a mid-level conduit material because it has thicker walls than electrical steel conduits but thinner walls than rigid metal ones. Intermediate metal conduits come in steel but can be coated with other materials. Intermediate metal conduit is threadable, but you can also use it with clamp-style fittings.

Liquid-Tight Flexible Metal Conduit

Liquid-Tight Flexible Metal Conduit is a sub-type of flexible metal conduit. A plastic waterproof coating covers LFMC, and Its interior is similar to FMC. LFMC is best for wiring in damp locations.

It can also be put in the ground or embedded in concrete. Many different LFMCs are depending on the type of resistance you need. There are LFMCs for extreme temperatures, oil resistance, anti-bacterial and flame resistant.

What Are The Different Steel Conduit Sizes?

There are several different steel conduit sizes available on the market. Before purchasing steel conduits for electrical work, check all the other steel conduit sizes to see which works best for your wiring needs.

At Meteor Electrical, you can find multiple steel conduit sizes for any electrical work. The steel conduit sizes range comprises 20mm, 25mm, and 32mm. There are steel conduit sizes ranging from 38mm to 50mm for larger conduits.

Other steel conduit sizes on the market include 1 ½” and 2” diameter conduits. The steel conduit sizes offer a wide range of applications to protect your wiring.

FAQ's

- What is Metal Cable Conduit used for?

- Where can I use Metal Cable Conduit?

- Why would Metal Cable Conduit used?

- Can Metal Cable Conduit rust?

- What are the Galvanised Steel Conduit sizes available?

- What are the benefits of using Metal Cable Conduit?

- Can I install Metal Cable Conduit inside my walls?

- Is Metal Cable Conduit recyclable?