Cable Trays & Baskets

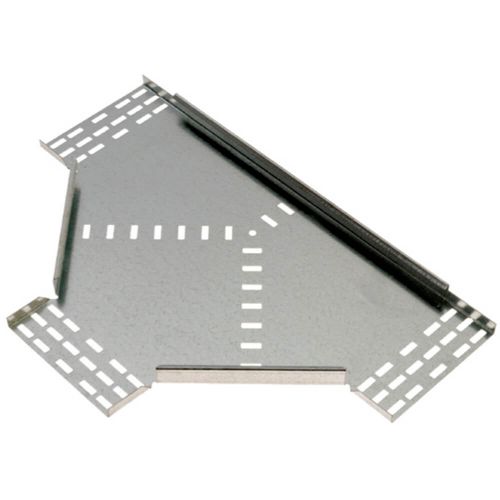

Electrical trays and cable baskets offer a secure open option for cable and wire routing. Cable electrical trays are a track that allows cables and wires to be routed throughout a structure in an easily maintenance way. They can be placed on a wall or hanging from the ceiling. Cable baskets, which are frequently constructed of galvanised or stainless steel, not only provide a suitable cable management solution but also look visually good in any setting.

Types of Electrical Cable Trays:

We have a wide range of Electrical Cable Trays to suit any applications. We stock:

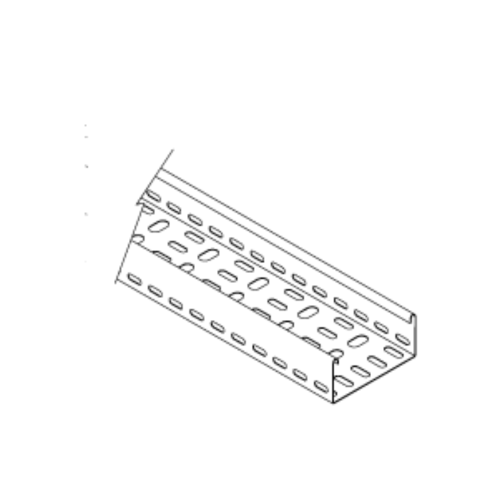

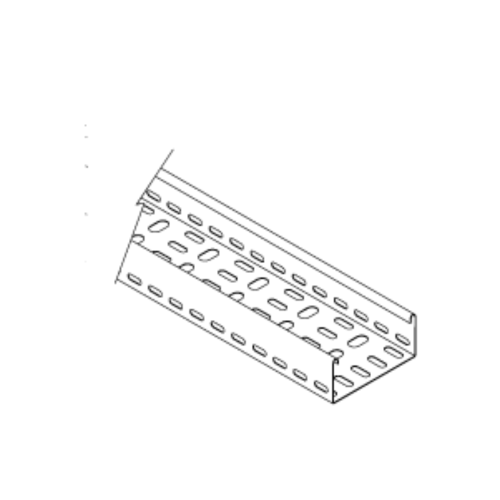

- Light Duty Metal Cable Trays

- Medium Duty Metal Cable Trays

- Heavy Duty Cable Trays

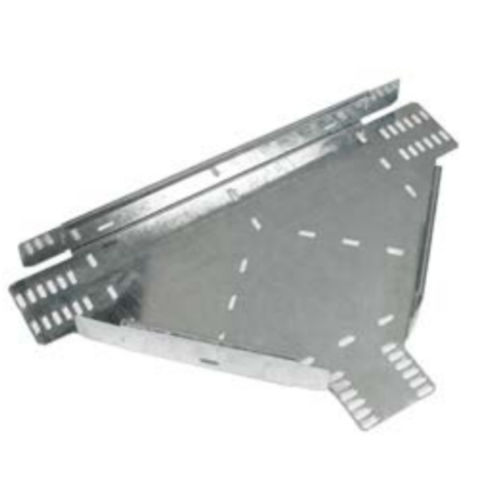

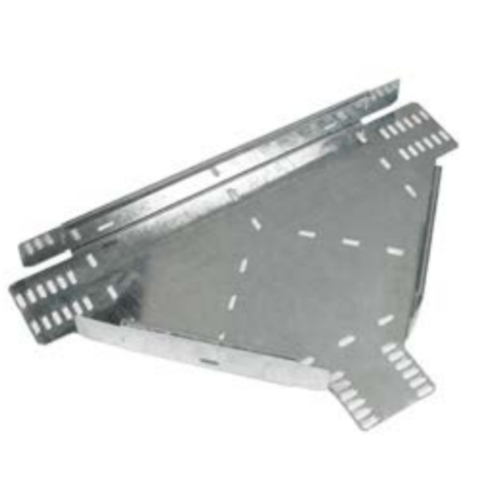

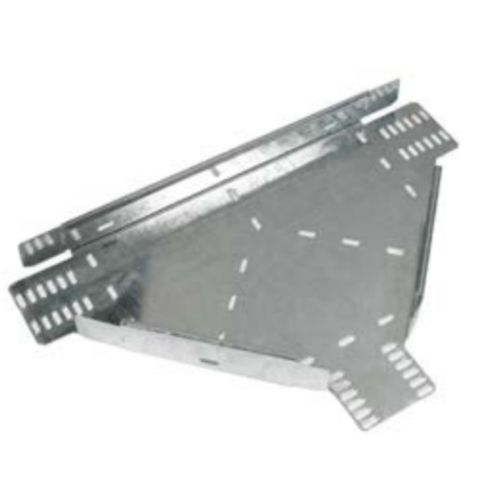

Types of Cable Baskets and Cable Trays:

At Meteor Electrical, we stock a wide range of cable baskets and electrical trays including:

- Suspended cable trays

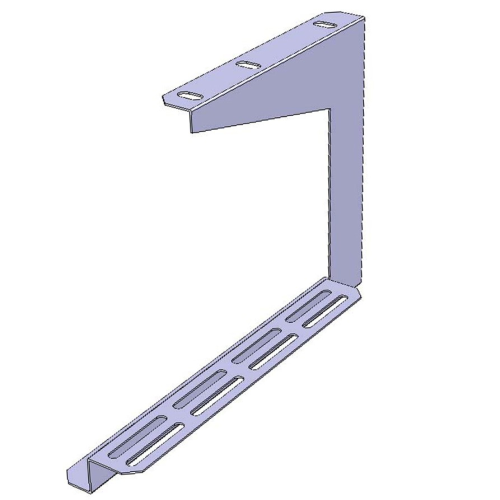

- Cable tray hangers

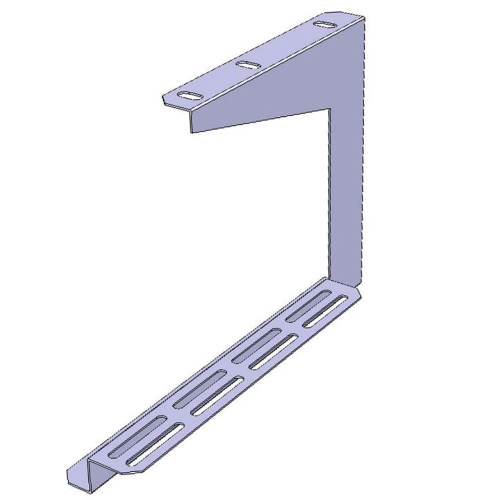

- Stand off cable bracket

- Fixing coupler

- Nut, bolt and clamp assembly

Shop our extensive range of cable baskets and trays from our selection of cable management supplies; including 100mm baskets, heavy duty cable trays, pre-galvanised cable trays, coupling baskets, brackets, and more. Order online today to receive next day delivery!

What are Cable Trays & Cable Baskets?

A cable tray is a cable management system that enables the safe and secure transport of wires across open areas and provides cable protection against overheating and fire buildup issues. The most commonly used supporting cable trays include a solid bottom, perforated, ladder, wire mesh, and channel type.

Cable trays are mechanical support systems that can manage anything from electrical cables and raceways to insulated conductors for electrical power distribution. There are various cable tray sizes to choose from at Meteor.

A cable basket is the best electrical solution for routing and supporting multiple cable runs at the same time. Cable baskets oftentimes have a wire composition that allows air to circulate for proper cable ventilation. There are cable basket solutions for areas such as under desks, raised flooring systems, or hanging tray set-ups.

There are many advantages that come with an electrical cable tray and cable basket, and some of them include low maintenance costs, high durability, space-saving, high quality and strength, optimum protection, and corrosion resistance.

Features of Cable Trays & Cable Baskets

There are many important features of cable trays. Electrical cable trays carry a suitable aesthetic for when they are used in public areas and are available in various colors to match the look of the building they are being placed in.

In addition, cable basket trays are the best and most aesthetically pleasing option in buildings where there is no paneled ceiling; electrical trays can be great for hiding cables while keeping them organized at the same time.

Cable trays have a single sheet of metal and may have different kinds of slot patterns which make it easier to position equipment and fasten cable tray hangers, cable ties, and other fixings. An electrical tray is also the best choice for light electrical and instrumentation cables and tubing. Covers can also be added to the cable trays to protect cabling against UV, vandalism, and various weather conditions.

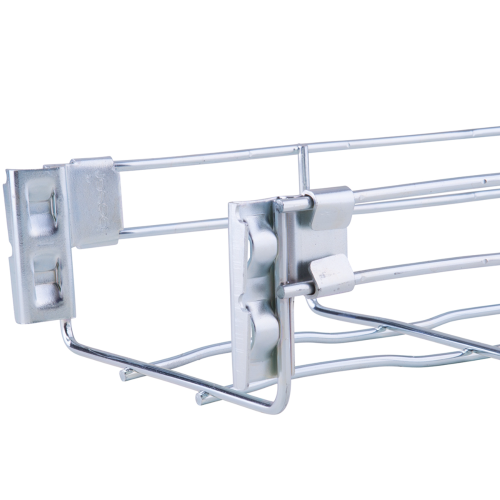

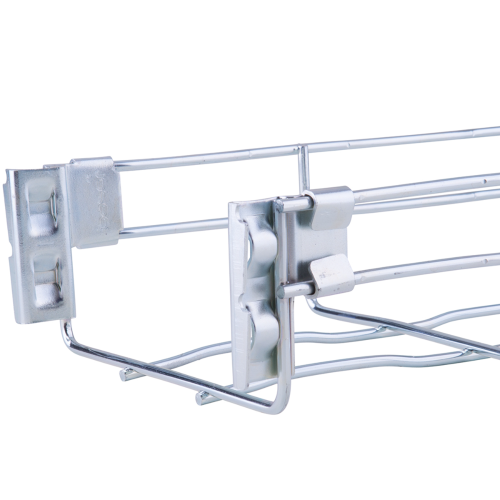

How Does a Suspended Cable Tray Work?

Traditional electrical cable tray installations pose a variety of restrictions and issues because of their lack of versatility; there is hardly room for adjustments because of the limitations it poses because of being made by rigid threaded bars.

A suspended cable tray system is a flexible electrical tray management system that provides just as much strength and reliability that a traditional cable basket tray would. In addition, a suspended cable tray is versatile enough to be changed according to whatever the needs of the user may be.

While generally cable trays require a large range of expensive heavy materials that are difficult to install, suspended cable trays simply use wire rope and a locking device. This is more cost-effective while still being up to high standards. Suspended cable trays allow a good route for wires and cables to run through, and use cable tray hangers/cable basket hangers to suspend the tray from the ceiling, fix it to a wall, or have it floor mounted.

What types of cables can be installed in cable tray systems?

There are various types of cables that can be installed in cable basket tray systems, and some of these include power and control tray cables, power limited tray cables, instrumentation tray cables, optical fiber cables, fire alarm circuit conductors, communication cables, mineral insulated (MI) cables, and metal-clad (MC) cables.

Instrumentation tray cables are available in shielded or unshielded constructions consisting of multiple single conductors, unshielded or shielded twisted pairs, and with or without metal armor. They are specifically designed for use in power limiting circuits.

Metal clad (MC) cables are assemblies of one or more insulated circuit conductors that come with or without optical fiber members enclosed in an armor of interlocking metal tape, or a smooth corrugated sheath. In other cases, a plastic overall jacket can be used as well.

Mineral (MI) insulated cables are typically a factory assembly of one or more conductors that are insulated with highly compressed refractory mineral insulation. This insulation is usually made up of magnesium oxide, and enclosed in a liquid-tight and gas-tight continuous copper or alloy steel sheath.

MI cables are also more resistant to fires than their plastic-insulated counterpart – they are used for high-temperature applications or critical fire protection applications such as alarm circuits, smoke control systems, and fire pumps. They are not permitted to run underground unless specifically protected from physical damage, when necessary.

Optical fiber cables or fiber optic refers to the technology associated with the transmission of information as light impulses along with a glass or plastic wire/fiber. Fiber optic wires are much more capable of carrying large amounts of information compared to the conventional copper wire option. In addition, they are far less subject to electromagnetic interference.

Communication cables are similar to optical fibers in the sense that they are also used to send information signals primarily. This is accomplished by integrating coaxial conductors, copper conductors, or twisted wire pairs.

These cables are used in a wide variety of applications including recording studios, radio transmitters, intercoms, etc. Since communication cables are often routed through air circulation spaces that don’t contain any fire barriers, extra caution has to be taken and they have to be coated in a material that won’t contribute to the spreading of flames in case of fire.

Fire alarm cables are classified as either power-limited or non-power-limited. They are also known as power-limited fire alarm cables (FPL-FPLP) and are solid or stranded copper.

They are also not allowed to be placed in cable trays where electric light, power, Class 1, non-power limited fire alarm, and medium-power network-powered broadband communication circuits are present, unless separated by a barrier. It is not permitted to install audio system circuits in the same cable or raceway as PLFA conductors or cables either.

It is important to note that medium voltage (type MV) and single conductor cables in sizes 1/0 and bigger are permitted with some restrictions attached to them in industrial establishments. You will have to get a qualified professional to service this installation.

How do I choose a cable tray size?

The correct cable tray size equals the width multiplied by the loading depth. The best way to tell whether you have the right cable size or not is by seeing when it appears 50% full of cable or wire.

Cable tray size width requirements are generally 12.84 inches and 11.77 inches. A cable tray size of 30-inch width should be used if space between cables is accounted for. Most electrical cable trays are designed to hold a weight of up to 200 lbs.

How to Select the Right Cable Basket Tray

There are a few things to keep in mind when deciding which cable basket will be the best for a specific application.

Types of Wires

Take into consideration whether you need to organize low-voltage or high-voltage wires. What kind of material do you need the wires to be made from, and approximately how hot will the cables get?

Specific cable basket trays help ventilate the heat while others do not, so knowing these details is important. In addition, there is a need to consider how many wires are needed to manage and how heavy they are.

Location Conditions

Some locations may have a risk of moisture, fire, as well as ventilation. The conduit properties of the location, if there are any, should also be taken into consideration to ensure that the wires you obtain can transfer the data correctly.

Length of Support

What length will you require from the cable basket tray? It is necessary to consider this as particular cable baskets provide support for cables that span a much greater area than others. Besides considering how much assistance is required in the present, analyzing the changes that may be required in the future is also important.

Use of Electrical Cable Tray in Buildings

Every building that gets constructed requires a large amount of wiring – in order to manage this huge amount of wire, electrical cable tray systems are needed to help support insulated cables which are used for power distribution, control, and communication.

All kinds of cable trays are involved in the process, be it a bending cable tray, suspended cable tray, cable basket tray, etc. A good electrical cable basket try system is used as an alternative for open wiring or electrical passage systems. They are specifically helpful in cases where changes in the wiring system will be required in the future.

An electrical tray is a very efficient and useful tool when it comes to managing a mess of wires. Cable basket trays are able to separate power wiring and data/communication cabling, and all you need for this is a single, large cable tray installation.

Electrical cable tray installations are capable of routing an oversized amount of wiring, and as a result, there won’t be a mess of conductors where locating faults would become difficult.

The cable tray will follow the perimeter of the area within the room, power, and information conductors will enter and exit at various locations. In cases of raceways terminating at a receptacle, cable tray hangers/clamps or cable basket hangers can be used to fasten the raceway to the cable tray system.

Depending on the location and application, a variety of cable trays are employed within a building. One of the most common types used is a solid-bottom receptacle cable tray because how it provides the most protection to cables.

Use of Cable Baskets in Buildings

Cable trays made by using wire mesh – cable baskets – are used where there is a large number of tiny cables involved. At times, large power cables set within the tray might need support blocks to take care of spacing issues between conductors and to stop the overheating of the wires.

Smaller cables can also be set unsecured in horizontal cable basket trays or secured with cable ties to the lowest of vertically mounted cable basket trays. For the backing of cables at elevation changes or the direction of a receptacle, a large range of specialized cable basket fittings can be created that are compatible with every manufacturer's style.

How are electrical cable trays created?

Cable trays are made up of unendingly chilly moved steel in order to make them light weight for production, and are then hot plunged toughened to give them shape. Electrical cable trays can be created out of various materials such as fiberglass-strengthened plastic (FRP), aluminium, or steel.

Why are Cable Trays Needed in Industries and IT Companies?

Within various industries and IT companies, electrical cable trays are needed inside of buildings to course wires inside of an organized pathm as opposed to running them over roof spaces and dividers uncovered.

The electrical cable trays are made to manage security wires or electrical, information transfers, etc. In fact, most national and construction standards make use of the benefits cable trays bring in various ways.

As technology takes over the world at a fast pace, it has given cable tray manufacturers a motive to continue and come up with several different types of cable trays; there is a growing interest in complex types of cable and wiring lying that needs to be accommodated for in these industries.

Pre-Galvanized & Galvanized Cable Tray Coatings

Galvanized coatings for cable trays are the most popular type because of how cost-effective they are. In addition, it protects the electrical tray from numerous environmental chemicals and is self-healing if by chance an unprotected area garners scratches and cuts.

The way it is made is through steel being coated with zinc through electrolysis – the steel cable tray is then dipped directly into a bath of zinc salts.

Pre-galvanized coatings are done in a rolling mill by passing steel coils through molten zincs. These coils are then processed to be slit to size and fabricated. Cuts and welds are some areas that are not normally coated during fabrication because they are protected by neighboring zinc which works well as a sacrificial anode.

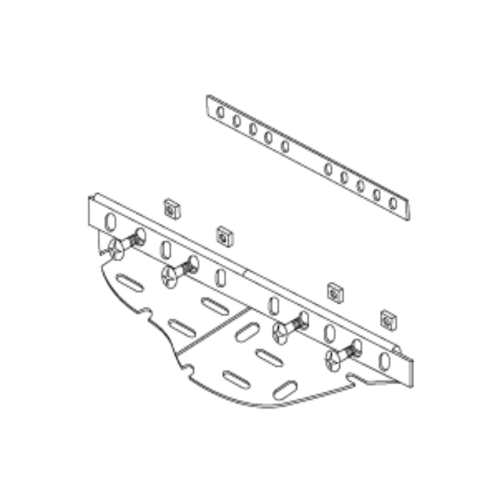

What is the thermal expansion and contraction of cable trays?

The process of therman expansion and contraction affects the cable tray system as a whole. This must be taken into consideration during the installation process, but it is necessary to determine the number of expansion splice plates needed beforehand.

This will be used to decide the length of the straight cable tray runs and the total difference between the maximum summer and minimum temperatures. The expansion splice plates have to be allowed to function properly, and to do this an accurate gap setting between the cable trays is required.

Basically, the support nearest the midpoint between expansion splice plates should be anchored and it should also allow the cable tray longitudinal movement in both directions.

Moreover, the electrical cable tray system may be used as an equipment grounding conductor and so it is important to use bonding jumpers at all expansion connection points to keep a continuous flow in the electrical circuit.

FAQ's

- What are the cost advantages of Cable Tray Wiring Systems?

- What are the different types of Electrical Cable Tray?

- How do cable trays work?

- What is a ceiling cable tray?

- What is the difference between cable ladders and cable trays?

- What type of wiring do cable trays support?

- Are tie-down cable installations necessary in a cable tray?

- Can high voltage cables be installed in cable basket trays?

- Can a multiconductor cable be installed in the same cable tray?

- What is the difference between a cable ladder and a cable tray?