Industrial Switches, Sockets & Plugs

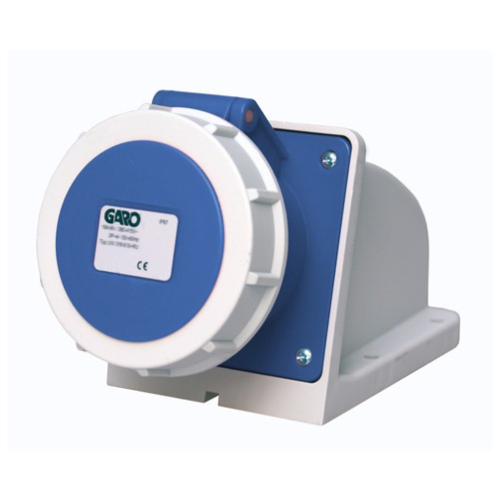

Suitable for power applications in industrial environments, this range of industrial plug sockets and industrial socket outlets are offered in two different versions: straight mobile and 10° flush mounting. Easy to assemble with a locking system that prevents unwanted disconnection.

The 16 to 32 amp versions require screw or quick spring wiring, while the 63 to 125 amp recruit a branching terminal connection technology.

There are many benefits to our range of industrial plugs and sockets, including:

- Their extreme resistance to mechanical stress

- 4 Ingress Protection (IP) levels for total protection

- Safe and intuitive assembly

Extreme Resistance to Mechanical Stress

The use of high performing technologies and the coupling of moulded rubber parts offers extreme resistance to elements most exposed to impact and mechanical stresses, with an IK09 rating.

IP Levels for Total Protection

Included in our range is HP mobile plugs and socket outlets, the first on the electrotechnical market to offer an ingress protection of 68 and 69. The nickel plating of pins in the industrial plug sockets and holes of the industrial socket outlets offer further protection against corrosion and abrasion, even in critical environmental conditions.

Safe & Intuitive Assembly

The 63 to 125 amp versions have a locking system with captive screws screwed on brass inserts made with wider contrast flange. Whereas the 16 to 32 amp versions have a body grip locking with safe lock ¼ turn.

The introduction of all the clock references for the earthing contact completes the range for specific applications and installations.

Safety, reliability, and robustness is guaranteed with our range of industrial plug sockets and outlets. Available instore or order online for next day delivery. Browse our full range of switches, sockets, and wiring accessories here.

Industrial Switches and Sockets

In an industrial setting, it’s crucial to have suitable switches and sockets that can handle heavy loads and support heavy machinery. These electrical components should also come with several safety features to protect wiring from various hazards.

Before you select your ideal industrial switches and sockets, there are several things you must consider.

Why Are Industrial Switches and Sockets Important?

Industrial sockets and plugs provide connectivity to the mains supply and machinery. These special plugs are crucial because they work with voltage and current at a higher rate than a household power supply.

Typically, you would use industrial switches and sockets in polyphase systems with a high current or areas requiring extra protection. Industrial settings often have a higher risk of hazards, so opting for durable and long-lasting components is essential.

The best way to determine the strength of an industrial plug is by checking its ratings and certifications. This is the best way to ensure you get the right product.

Some industrial plugs and sockets may have waterproof sleeves and covers or be interlocked with another switch to prevent disconnection. You can also find specific switches and sockets according to the industrial sector where they will be installed.

Industrial Plug

This type of plug consists of a connector, holder translator and pins. Industrial plugs usually have a protective sleeve that prevents dust and other debris from accumulating in the plug.

These plugs are manufactured especially to withstand high voltage and currents while strengthening connectivity. You can also find nickel plating on this component to protect against corrosion.

Industrial Socket

This component is crucial for connecting the electronics to the main power supply. Industrial sockets are hollow devices that act as the power output for heavy machinery and industrial appliances.

Like the industrial plug, these also come with a protective coating that ensures safer handling and lowers the risk of hazards. Unlike traditional sockets, this component also has a higher power output and can withstand industrial electrical dangers.

The Types of Electrical Switches Used In Industries

Let’s look at different electric switches commonly found in industrial settings.

Single Pole Electrical Switch

A single pole or one way switch is the most common type of electrical switch. You can easily recognise this device due to its simple on-and-off marking.

Single pole switches are commonly used for controlling lights, fans, appliances and sockets from one location. The simple toggle in a single pole switch sets it apart from other configurations of electrical switches.

Single pole switches come with two brass coloured screw terminals on its body. One of these terminals is connected to the current carrying wire. The other terminal is used for the outgoing current-carrying wire.

Most single pole switches also include a ground terminal that connects the circuit’s grounding wire. When this switch is turned on, the two terminals become connected. When it’s turned off, the contact between the two components is broken.

Usually, neutral or blue wires are not connected to this electrical switch. If there are two neutral wires present in the circuit box, they are typically joined so that they can remain in the box without touching the electrical switch.

If a blue wire is connected to the switch, it’s functioning as a hot wire. If this happens, you should wrap a piece of black tape on the wire close to the switch to indicate that it's operating as a hot wire, not a neutral one.

Double Pole Electrical Switch

A double pole or two way electrical switch is usually what you find in industrial settings.

Like the single pole version, this two-way electrical device sometimes also has the on and off marking on the body. With this switch, you can control any equipment or device from multiple locations.

Double pole switches are commonly used for equipment with a 30 amp capacity, which is why they are common in high-voltage commercial settings. This means they can control appliances with a higher capacity, such as heavy load-bearing machinery, assembly lines etc.

A two way switch has four brass terminals carrying hot wires. This switch also has a ground terminal, allowing you to connect it to more than one hot wire. To better understand this device, just think of two single pole switches combined to form one switch.

It’s important to note that one of the terminals can connect to the remaining two. However, both terminals can’t connect at the same time. When you connect with one terminal, the other one gets interrupted.

Three Way Switch

Three way electrical switches are ideal for controlling one appliance from two different wall locations. A triple pole switch has three terminal screws.

Depending on where this device falls in the circuit system, the darkest screw terminal is connected to the hot wire from the energy source. It can also be connected to the hot wire running to the light fixture.

The rest of the screw terminals are connected to traveller wires that link two triple pole switches together. These electrical switches also have a green grounding terminal with a copper grounding wire attached.

Four Way Electrical Switch

Even though this switch is not used as commonly as the other options, they are still functional in several places. A four way electrical switch is made from two three-way switches, providing control for a light fixture and outlet from multiple areas.

For example, you own a large warehouse space which would make controlling each outlet time-consuming. If you want to control a single fixture from five different places, a four way switch will be ideal. You can also add a few three way switches in between for even more functionality.

In terms of the switch body, this device has four terminals plus an additional ground terminal. Two of these four terminals are typically brass, while the others are dark.

But unlike the three way switch, you won’t find a common terminal here. Essentially, the four way switch acts as a switching device for the travelling cables between a three way switch.

Practice Caution

With a four way electrical switch, you may need to take extra precautions while handling it. Be very careful when you choose to replace a four way switch.

Remember that the terminals have two unique layouts depending on which manufacturer produces them. One is IN on the left and OUT on the right. The other is IN at the top and OUT at the bottom.

Flow Switch

A flow switch is designed to make or break an electrical circuit. In an industrial setting, flow switches are necessary because they monitor and control the rate of energy. These devices are crucial for ensuring safe and manageable operations in industries.

What Are The Benefits of Industrial Switches and Sockets?

As mentioned before, industrial electrical devices are crucial because they ensure all operations run smoothly in an industrial setting.

With this in mind, here are some important benefits of industrial switches and sockets.

Keep Track Of Electricity Flow

All industrial sockets and plugs are created with extra safety measures, including circuit breaker features that identify an unusual electrical flow. This feature keeps your machinery and the people using them safer.

Suited for Heavy Industrial Machinery

Since industrial appliances consume a lot of energy, they need high-voltage switches and sockets. These electrical components are crucial as they protect the equipment and the person operating them.

If you don’t use industrial-grade plugs and sockets, there will be a higher risk of workplace hazards.

Deal With Industrial Wear and Tear

Apart from protecting circuits and people, industrial-grade sockets and switches can also handle an industrial environment's general wear and tear.

These are designed to work well in any kind of environment - whether it's high-humidity spaces or freezer-cold storage areas, industrial sockets can handle anything. Often they are made from a high-quality thermoplastic material that maintains its integrity.

Easy to Handle and Use

Even though you might need a professional to install these components, industrial switches and sockets are fairly easy to use. You don’t need to follow any complicated measures to use these devices.

An Inexpensive Option

Industrial switches and sockets are fairly inexpensive and cheaper to use than other special components performing the same function. In addition, the protection offered by these devices helps you save on future maintenance and replacement costs.

What Are The Best Industrial Switches and Sockets?

With so many options to choose from, here are some of the best industrial switches and sockets.

Switch Modules

If you’re flush-mounting your industrial switches and sockets, you need a suitable component to make installation easier. The switch modules have a smooth, seamless structure easily integrated into any flush-mounted panel.

Moreover, you can create multiple combinations and connections with a straightforward switch. This extremely versatile switch also works well with surface-mounted plates as well.

Our Gewiss’ 1 gang switches are available in a single-pole or double-pole configuration to fit every electrical combination.

These switches come in a bright white shade with a smooth surface that is easy to clean and maintain. You can mix and match different switches to create your ideal switch plate.

Eclosed Switch Modules

For outdoor switch installations, you must invest in IP-rated enclosed structures. The best option for industrial settings is enclosed switch modules which are highly functional and protect electrical equipment from damage.

These enclosures are built with a minimum IP rating of 55 to protect against various atmospheric hazards. This protects your switches to ensure they keep operating for a long time.

The high-quality thermoplastic adds to the durability of your fixture, ensuring that it lasts a long time. These boxes are also constructed with a transparent door, giving you a clear view of the switches.

Meteor carries Gewiss enclosed modules which are highly functional and provide added protection. Our Gewiss switch modules are available in the following formats:

- Single Pole One Way Switch: an enclosure with one switch for simple installations.

- Single Pole Two Way Switch: this switch is also enclosed in a hazard-proof box for multifunctional switching.

- 2 Gang Two Way Switch: here, you can find two switches which can be programmed to cover a wide range of functions.

- Module Enclosure Box: if you want to customise your outdoor switches, Gewiss also carries a modular switch box. This lets you put whichever button you want according to your needs. You can choose between a 3 or 4 module option based on how many switches you need.

Another great benefit of enclosed switches is that they work well in multiple locations. While you commonly install them in commercial or industrial properties, you can also integrate them in domestic outdoor living spaces.

Straight Plugs and Connectors

In areas where maintaining electrical safety and integrity is essential, having straight plugs and connectors will make a big difference. These components are designed with expert knowledge and care to ensure an excellent end-user experience.

As with other products, these also come with IP-rated construction for outdoor installations. The exact IP rating will depend on the choice of the connector, with options ranging from 44/54 to 66/67/68.

Depending on your needs, you can opt for a straight mobile or flushed appearance. Furthermore, you can choose between 16 to 32A based on your system’s requirements.

Our Gewiss straight plugs and connectors are also colour coded and available in blue, red and yellow shades for better visibility and organisation. You can colour-code the connectors to identify and keep them separated from other components.

Surface Sockets

Opt for a connector with an angled surface if you're looking for surface-mounted sockets designed to fit multiple installations. These components are positioned at a 10-degree angle for better mounting.

The screw wiring provides an uninterrupted connection and is ideal for indoor and outdoor installation. These high-grade electrical sockets are constructed according to international-level performance standards to guarantee an exceptional operating standard.

This socket's thermoplastic material is crucial as it protects you and your circuit. The materials are weatherproof, waterproof and also safeguard from chemical hazards. As with the previous switches, these also come in various amps and voltage ratings to fit any installation.

Switched Interlock Sockets

The best way to keep your electrical system safe is by opting for quality components. Industrial switched interlock sockets are expertly crafted to keep your circuit safe. These sockets make it easy to manage and distribute the electrical load in industrial and commercial properties.

Interlock connectors can be used in horizontal and vertical configurations for several operations. You need to get only the best device to ensure proper handling. Gewiss has constructed these components according to the highest safety standards to ensure safe operation.

The materials used also protect the socket’s structure and minimise potential hazards. This socket features an interlock mechanic, including circuit breakers and a rotary switch. You can also find a fuse holder base on some models for better performance.

Combining all these features leaves you with a highly versatile product that can be back-mounted or flush-mounted.

FAQ's

- What are industrial & multiphase power plugs and sockets?

- What are industrial plugs & sockets used for?

- What are interlocked sockets?

- What are 3 phased plugs

- What does a 3-phase plug look like?